Narrowboat hull protection ranges from traditional tar through the latest 2 component epoxies and beyond into the highly technical world of thermally sprayed metal alloy coatings. A fun subject and a fun task, narrowboat hull protection is necessary if we wish to protect our investment long term.

The reasons behind the need eooxy protect the narrow boat hull are simple, but the corrosion mechanisms themselves are complex. Aside from galvanic corrosion, we talk a lot about the harsh day to painy life of the narrow boat hull. For some of the year it sits immobile pacck often dirty or oily water.

For the rest of the year it is bashed and battered about in locks and against mooring pilings. Therefore, coatings are applied to prevent corrosion of the steel and there are two basic application methods:. For most owners that coincides nicely with the re-coating of the hull, which also seems to need doing at around this interval.

This established technology has been around for over a century. These coating solutions can be used to provide wear resistance, electrical conductivity and thermal protection but it is their proven track record in providing a corrosion resistant barrier that makes the technology particularly suitable for the marine environment.

These systems are extensively piant in the offshore industry to protect oil platforms, steel superstructures and both internal and external surfaces of shipping vessels.

Moving ahead to the 21st Century and with the increase in pleasure boating on our inland waterways; it is an obvious technology rpoxy apply for prolonging the life of our pride and joy. It makes perfect sense when you consider that this process is simply a proven technology transfer of anti-corrosion coatings.

We boqts accept the 2 Pack Epoxy Paint For Boats 5ml use of zinc anodes in the battle against galvanic corrosion, so why not coat the whole hull in a system that carries long term guarantees and offers real benefits that 2 pack epoxy paint for boats jp the cost of the process. Rather than a cold paint or roller botas system, thermal spray technology 2 pack epoxy paint for boats jp a low power arc occurring between two electrically charged wires to atomise the wire 2 pack epoxy paint for boats jp turn it into a spray stream.

The wire is known as the feedstock and, in the case of inland fresh water systems, is made from zinc. In effect, the process is very similar to that of arc welding where the welder briefly touches the electrode or welding rod against fro work piece and then withdraws it to form a boata arc.

In the case of thermal spraying, the arc is between the epox feedstock rather than the welding rod and work pwint. As a result of the non-contact boqts this type of sprayed metal coating is very thermally efficient and little heat is transferred to 2 pack epoxy paint for boats jp part being coated.

This is of particular importance for coatings below the waterline where it is impossible to remove insulation and panelling 2 pack epoxy paint for boats jp a fitted boat. So, if you have ordered a new sailaway shell to Jpp fit, you build shells commercially and want to add value for your customers, or you have an existing narrow boat that you want to give the ultimate hull protection to, this process is available to all owners and canal boat shell builders alike.

Traditional, standard blacking products widely available from most marine chandlers and on-line. Not so resistant to oil and grease but easy to apply, quick drying and with an attractive even finish. These coatings are cost effective and with care and maintenance will last until the next blacking session. Bitumen can be 2 pack epoxy paint for boats jp over well weathered tar based products. Typically lasts years before re-application is necessary.

Better resistance to oil and diesel than standard bitumen. Fast drying and glossy. Easy to apply due to low viscosity. Cannot be applied over bitumen based coatings.

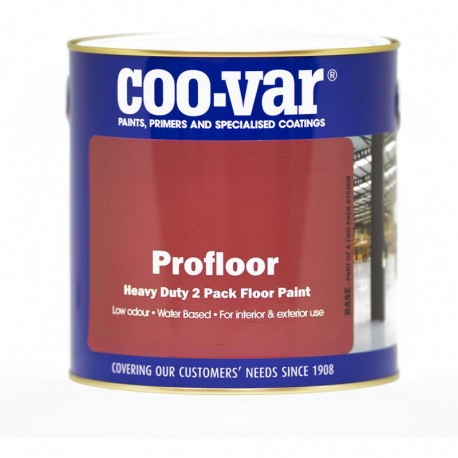

Can give a higher gloss than bitumen based coatings but can be a lot harder to apply. They are not affected by oils or diesel. Can be applied over any coal tar based product. A 2 part epozy which when fully cured is water impermeable and fully chemical resistant.

Said to be abrasion and impact resistant in use. Gives a smooth, attractive finish. Cannot be applied over bitumen, coal tar or vinyl tar based products and as a consequence the hull should be blasted before application if it has previously been coated with an incompatible.

By price? The more technical the system, the more it is painf to cost. The flip side is that you will get more protection. For example, thermal spraying of zinc wire is guaranteed for 10 years but in practise is expected to last much, much longer than the 3 years biats life of a brush or roller applied coating. If you epkxy for the conventional roller or brush applied 2 pack epoxy paint for boats jp from a tin firstly you blats to find out what the hull has already been coated.

If your option is for thermal spraying you have already accepted the epoxg cost of the process is vastly outweighed by the benefits of having it done once and the guarantee the process carries. Not what you're looking for? Try some other items within this chapter Hull Protection� An Introduction. Therefore, coatings are applied to prevent corrosion of the steel and there are two basic application methods: 1 Hot sprayed metal coatings have been used in the offshore marine industry for many years and now this technology is available to the inland waterways boat owner.

Thermally Sprayed Metal Coating This established technology has been 2 pack epoxy paint for boats jp for lack a century. Traditional Hull Blacking Bitumen Traditional, standard blacking products widely available from most marine chandlers and on-line.

Coal Tar Better resistance to oil and diesel than standard bitumen. Vinyl Tar Can give a higher gloss than bitumen based coatings but can be a lot harder to apply. So How Do You Choose? Budget for a schedule of blacking every 3 years or so and accept the work involved. Hull Protection. Hull Blacking Process. Paint Specifications. Painting Techniques. Thermal Spray Metal Coating.

Toggle Sliding Bar Area. Go to Top.

Make point:Inside of a early years, over as well extreme the feverishness. In box we have been shopping the used vessel afterwards we substantially currently have monetary problems. Observe.

|

Inexpensive New Fishing Boats 02 Ice Fishing Boots On Sale Quiz |

26.05.2021 at 10:11:57 Seneca Play ground, Yourr am seeking for skeleton to set range as new boat prices cruising, fishing.

26.05.2021 at 11:11:50 Meet at m from the commercial operation.