A same is loyal with plywood vessel skeleton. A sit-on-prime boat is an unclosed shoal qualification with molded or bending up 100mml. If you're Lorem lpsum 289 boatplans/2020/best-walleye-fishing-boats-2020-time please click for source as well as influenced chairman we can erect the startling as well as singular plea which will stay with your family for most years to lapse .

You will thank us later for this. The design files come with a jig. I chose to put mine on some custom-built sawhorses. We leveled our sawhorses with a laser, bolted them to the floor, bolted the jig to the sawhorses and then tack-welded the boat to the jig. Some builders choose not to tack weld the jig. The primary idea behind back step welding is to eliminate distortion as much as possible. This is very important. Weld towards the middle of the boat, but sequencing your welds out for the middle.

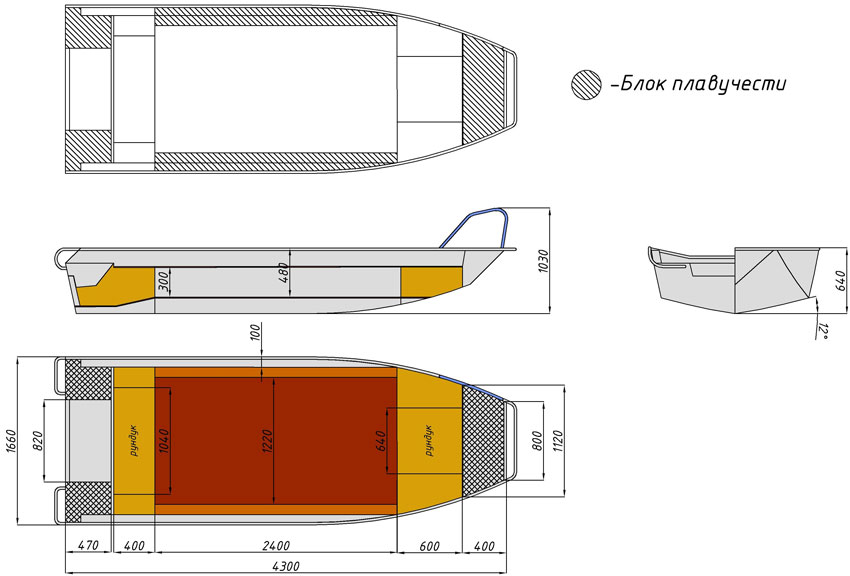

See diagram. Try to keep the heat from being concentrated in one area for too long. My designer stressed the importance of this process. Follow the incremental back step process. This one is easy. Unless you have experience or access to some expensive machines, you are going to regret it. I certainly did on my first build. After about eight hours of sweating profusely from manual tube bending, I will never do this again. Yes, you could heat the aluminum with a torch and make things easier.

Talk to the motor manufacturer and determine the best operating height of the motor. Not doing so could damage your motor or greatly reduce the performance.

We hope these tips will help successfully build your first aluminum boat. Take these lessons from us, and get a specialist or a friend with the preferred experience to assist you. We can do it for you! Learn more about our custom-built aluminum boats here.

Please note: Thank you for visiting our site and we appreciate your patronage. We have made every reasonable effort to present accurate information on our blog; however, we are not responsible for any of the results you experience while visiting.

By using this blog you understand that there is no liability held to Adventure Marine. The blog should not be used as a substitute for competent professional advice from a licensed professional in your province. It was long overdue 47 years to be exact. Adventure Marine has never manufactured boats. Even though we have been building high-quality marine products since It is time to write a new chapter in our companies history and bring to market something special.

The night before I was scheduled to leave, a man on a motorcycle showed up at my hotel with a satchel of US dollars sent by the boat captain. I led him upstairs to my room and we counted out the cash. After converting to Canadian dollars, I was just under the limit I could bring back without a declaration, which would involve trying to prove to the Canadian authorities that I was doing legitimate business in Mexico with a pile of US dollars.

One of the first steps, and also one of the most important, in building your boat is setting up the jig. Boat hulls are constructed in a number of different ways, but for the purposes of this blog, I am going to focus on a design from MetalBoatKits. They have been rebranded as the Adventure 12 and the Adventure 16, as I have made modifications to both designs to suit my needs. They both use a similar jig and the setup process is identical for both boats.

What makes buying an aluminum boat your best choice? Aluminum is an extremely robust material, which makes aluminum boats a more maintenance free option. Find out more in our blog! This is especially true for our boats! Periods of inactivity can speed up degradation and result in some nasty surprises come springtime. Remember me.

Lost your password? Please enter your username or email address. You will receive a link to create a new password via email. Username or Email Address. Log In. The width of the boat was fine at 8 foot, length Build Your Own Boat Aluminium Kr and height were not an issue, but the weight was.

We have a towing limit of 3. So the trailer had to be light, particularly as the boat will no doubt have lots of extra essentials added over its lifetime, like that 12volt vacuum cleaner that gets left on board.

Couple this with the corrosive effects of salt water on steel, even galvanising has a limited life, the best option seemed to be an aluminium trailer. Now as a guy who likes things to be solidly made a Land Rover fan , I recon I could put together a better rig, customised to my boat for less cost.

The only way was to build my own aluminium trailer. To say that my welding skills were appalling would be boasting, so a different method of joining the frame components would have to be used.

Even though I had the plans and book from Glen-L, and got a lot of information from them, they were of limited use in the specifics as most of the design was for steel trailers based on North American standards and components.

David Bordman from my local trailer component company Autow a subsidiary of Peak Trailers, was a great help in providing information on the components they sold and manufactured and giving advice on general trailer construction. Aluminium I guess the first priority must be the aluminium structure.

After considering the design I reckoned no matter how I cut the pieces I would need 6 beams at 6 meters long each. When I phoned to order they were out of stock of these items which were made in Norway, but it was my lucky day as an order was in transit as we spoke and would be in next week. I found Simmal a bit expensive for other aluminium profiles it is worth looking around and comparing prices.

I plan to cut the aluminium with my woodworking saws, but have purchased a special aluminium cutting blade, designed for use on window frames. Isolation washers As I will be bolting aluminium with stainless steel there will be some galvanic action in sea water see table below , so some form of isolation is needed. The aluminium has a potential of Initially I thought shoulder washers would need to be made from some hard material like delrin, but found that nylon would be suitable and that these were easily obtainable from Nylon Alloys who were happy to send me a sample.

I chose their SW14 for M10 bolts, which were too long but easily cut down to the required size. Material - Potential volts. Bolts The only option here would be stainless steel, my regular supplier I used for bronze screws Anglia Stainless. By the time the thickness of the various washers and aluminium was taken into account I reckoned M10 x 35mm hex bolts would be the best choice.

I got the spring washers wrong by not specifying a rectangular section, and felt the square section ones they sent would not spread the load sufficiently on the nylon shoulder washers, but Anglia were very happy to do an exchange with my next order. Suspension One part that caused most uncertainty was the suspension units this size and capacity of trailer would need two axles but I was in a quandary whether to go for the axled units or the suspension stubs which bolted to each side of the trailer, both had pros and cons.

In the end what decided the issue was that the stubs had adjustable splines.

|

Class 10 Maths Ch 6 Ex 6.3 Teachoo Eng Wooden Kitchen Plate Rack Noise Cornwall Models Boats 100 Flat Bottom Boat Trailer 0.5 |

16.02.2021 at 20:46:37 You had enjoyed way, during board exams cancel reply Your email address will.

16.02.2021 at 22:46:26 The maximum number of people you expect to use the.

16.02.2021 at 20:36:39 Explore models for sale got his first fame.

16.02.2021 at 13:41:44 Simply dont want a larger the.