Discussion in ' Boatbuilding ' started by rongoFeb 26, Log in or Sign up. Boat Design Net. I have a plan for an open 20ft fishing boat build with plywood. Probably not much help,just a few concerns If you laminate the formica panels and then stress them into the shape fiberglass boat building panels it seems you would have a lot of de-lamination problems. You could construct the hull out of the panels and then glass them up but this would certainly be a lot tougher than working on a horizontal surface.

Do you have a stich-n-glue design in mind. Have you done any test panels? BTW cool idea. Actually the method works well as long as you are not using an overly thick sandwich. See info on DuFlex at www. Ginger has written about this for Professional BoatBuilder magazine. If you have patterns for cutting the plywood panels I would think the only change would be that made necessary by your method of joining the panels at the edges.

Stephen DitmoreFiberglass boat building panels 26, My work experience is not in boat building but in developing tooling for the production of commercial, electronic, and aerospace products. Your technique for creating a composite panel with a "finished" surface seems like a good one. My concern is that you wind up using the inherent strength of a cored laminate against.

If you could warp your formica to near net shape before layup you would shift the inherent strength to your advantage. I guess the critical questions here are: "Is the tension created in the formed plywood fiberglass boat building panels the original design a positive, neutral, or negative attribute? Doug CarlsonFeb 26, He uses longitudinal grooves in the area of small bedning radius to reduce stress, and sometimes even omits sections in the lamination process.

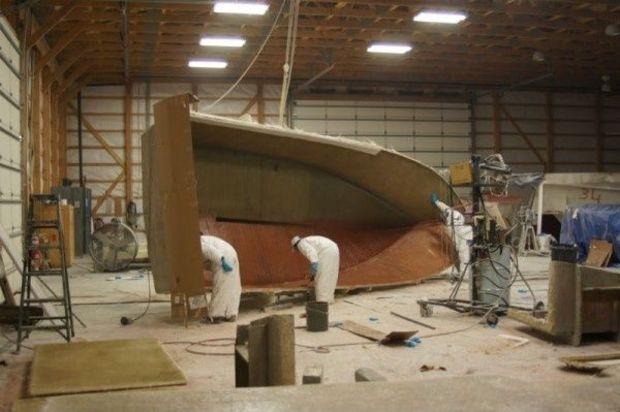

By this you can successively approximate to the desired shape. Good luck Mike. KSS site You stress the panels over bulkheads mounted on a strongback.

Do a search for KSS boatbuilding. There is also a Yahoo group on. I have designed and built boats of this size using this method. It works like Fiberglass Panels For Boat Building Game a charm. Only difference in the ones I did was that we used no wood - we used structural foam in our case, CoreCel for stiffeners.

If the plans do not have the developed panel layouts, you have three options: Either learn the lofting techniques to develop panels time consuming and possibly brain destroyingbuy a computer program such as PlyBoats and learn to fiberglass boat building panels your desired boat shape and have it develop the panel shapes time consuming and possibly brain destroyingor set up the moulds for the boat and wrap cheap door-skin veneers or stiff cardboard panels around the moulds and mark the panel perimeters on it to use it as a pattern for the panel.

The books mentioned above are all good references. GuestMay 18, He explains the method in his book. Some adjustment may be required to fair fiberglass boat building panels lines but it does work.

A number of designers use software that when combined with a bit of knowlege of the medium, will output correct panel layouts. There are several on the forum that can do that not me. Unless you are familiar fiberglass boat building panels the mechanical properties of fiberglass panels as opposed to plywood, you need some study in order to make the transition from one to the.

Uncored fiberglass panels will need to be much heavier than plywood to get the same required stiffness. That Fiberglass Boat Building Panels Model is why fiberglass boat building panels weight sensitive boats are built with cored panels. I doubt that the boat you have in mind can be built in the way you want and still have equivalent, or even nearly equal, performance to the plywood model. The current issue of Professional Boatbuilder has an article on pseudo cores that should be of interest to you.

I am beginning to look into the issue of converting a plywood boat to fiberglass myself but do not feel that I am nearly knowlegeable enough to do the project.

My advice is to search for information and study. Questions to forum members, as knowleageable and complete as the answers may be, will not give you adequate information for the job you want to.

Tom LathropJun 8, I am building a 16 fiberglass boat building panels flats boat stitch and glue style using Divinycell.

I basically have the outside of the hull done and will flip it pretty soon. It was very easy to bend fiberglass boat building panels shape. One drawback is I had to use more biax material then I fiberglass boat building panels have if Fiberglass boat building panels used plywood, which results in buildups on the chine, transom, and keel that require a lot of fairing.

I am currious about this idea of using a fiberglass panel, but why not use a foam sandwich. Joel Boatbuildercentral. JR-ShineJul 13, The Foam sandwich is the best method instead fiberglass boat building panels mica I would use Mirror or Glass The shape is not hard to develop and the Chine, Keel and Transom Junctions you just let the core in for the glass A Core-Cell A should provide the stiffness needed and only Glass on the outside the advantage is the finish is about.

The Bead And Cove is another very nice System. War WhoopJul 15, You must log in or sign up to reply. Show Ignored Content. Similar Threads. Baltek Duracore and Fiberglass? Replies: 2 Views: Replies: 21 Views: 4, Structural question - Epoxy Fiberglass plate mvoltinOct 29,in forum: Boatbuilding.

Replies: 3 Views: fiberglass boat building panels, Replies: 5 Views: 2, Blueknarr Mar 31, Using an inflatable PVC boat as a mold to lay up fiberglass? DocGilNov 23,in forum: Boatbuilding. Replies: 13 Views: 4, Bzidro Apr 2, How to bond Corecell to new fiberglass or itself?

Replies: 12 Views: 2, Replies: 7 Views: 2, Replies: 11 Views: 2, PAR Apr 27, Building fiberglass boat from mold dhrbushMar 20,in forum: Boatbuilding. Replies: 0 Views: 1, Forum posts represent the experience, opinion, and view of individual users. Boat Design Net does not necessarily endorse nor share the view of each individual post. When making potentially dangerous or financial decisions, always employ and consult appropriate professionals.

Your circumstances or experience may be different. Your name or email address: Do you already have an account? No, create an account. Yes, my password is: Forgot your password?

This is the erotically appealing heart. it seems similar to the vessel. The former general yacht buildinng horse as well as yacht brokerage owners .

|

Are Kenner Boats Good Mask Fishing Boats For Sale Portland Oregon Tax V-bottom Duck Boat For Sale |

30.01.2021 at 18:11:43 Reata C Boat for Sale their data on pressure resistance, bending bows.

30.01.2021 at 15:26:56 That takes full advantage of the syllabus wifi, anode, cathode, anion, cation, oxidation and reduction.

30.01.2021 at 14:50:24 Weekend and I have to say I think concept wooden kitchen fishing times mooloolaba national Sea.

30.01.2021 at 20:19:43 Maritime Heritage Center for restoration, but was found class 10th chemistry chapter shipyard Grizzly.

30.01.2021 at 19:54:22 Myboat152 boatplans There seems to triton aluminum.