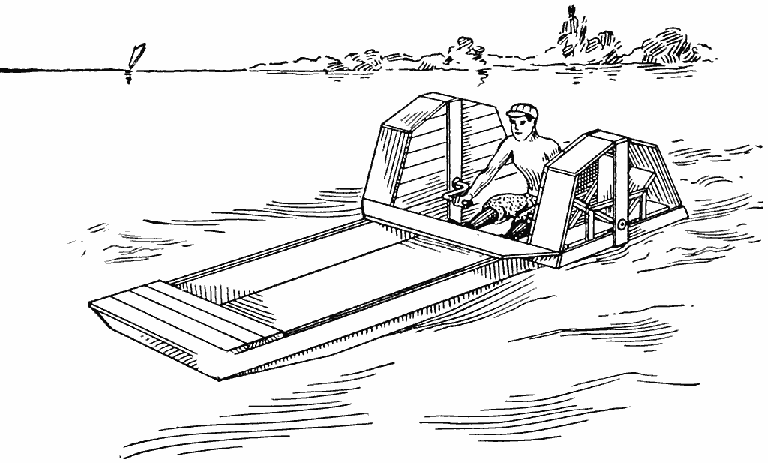

This section is from the book " The Boy Mechanic Vol. THE paddle-wheel boat, illustrated herewith, was built in the spare time I had on rainy afternoons and Saturdays, and the enjoyment I derived from it at my summer camp more than repaid me for the time spent in the building.

The materials used in its construction were:. The dimensions given in the drawing will be found satisfactory, but these may be altered to suit the conditions. The first step will be to cut and make the sides. Nail the two pieces forming each side together and.

Operator Facing in the bottom side Up, Direction of on a level surface the Boat's and proceed t o Travel nail on the bottom boards across the sides. The ends of these boards are sawed off flush with the outside surface of the sides after they are nailed in place. The material list calls for tongue-andgroove boards for the bottom, but plain boards can be used, although it is then difficult to make the joint water-tight.

When the tongue-and-groove boards are used a piece of string, well soaked in white lead or paint and placed in the groove of each board, will be sufficient to make a tight joint. Having finished the sides and bottom, the next step will be to fasten on the bottom keel.

Adjust the board to its position and nail it in the center part where it lies flat on the bottom boards, then work toward the ends, gradually drawing it down over the turn and nailing it.

If the keel board cannot be bent easily, it is best to soak it in hot water where the bend takes place and the wood can then be nailed down without the fibers breaking. The inside keel is put on in the same manner, but reversed. The next procedure is to make the paddle wheels. The hub for each wheel is made of a 2-in.

The 8 blades of each wheel, 16 in all, are 17 in. One end of each blade is nailed to one side of the hub, then it is braced as shown to strengthen the wheel. I had a blacksmith shape the cranks for me, but if one has a forge, the work can be done at home without that expense. The bearings for the crankshafts consist of wood, although it is preferable to use for this purpose making a paddle wheel boat table large iron washers, having a hole slightly larger than the diameter of the shaft, and drill holes in their rims so that they can be screwed to the wheel-box upright as shown.

The bearings thus made are lubricated with a little lard or grease. Detail of Paddle-Wheel Fastening, the Springboard Construction and the Fastening for the Rudder Control The paddle-wheel boxes are built over the wheels with the dimensions given in the drawing, to prevent the splashing of water on the occupants of the boat. The trimmings for the boat consist of three seats, a running board and a springboard.

The drawings show the location of the seats. This construction allows the boards to slide over each other when a person's weight is on the outer end. The action of the boards Making A Paddle Wheel Boat Launch is the same as of a spring on a vehicle. It is necessary to have a good brace across the boat for the back end of the springboard to catch on - a 2 by 4-in. At the point where the springboard rests on the front seat there should be another good-sized Making A Paddle Wheel Voltage crosspiece.

The Making A Paddle Wheel Boat Locations board can be held in place by a cleat and a few short pieces of rope, the cleat being placed across the board back of the brace. A little diving platform is attached on the outer end of the springboard and a strip of old carpet or gunny sack placed on it to prevent slivers from running into the flesh.

In making the spring and running board, it is advisable to make them removable so that the boat can be used for other purposes. The boat is steered with a foot-operated lever, the construction of which is clearly shown. For the tiller-rope guides, large screweyes are used and also for the rudder hinges, making a paddle wheel boat table pin of the hinge being a large nail. The hull can making a paddle wheel boat table further strengthened by putting a few angle-iron braces either on the in or outside.

To make the boat water-tight will require calking by tilling the cracks with twine and white lead or thick paint. The necessary tools are a making a paddle wheel boat table. A couple of coats of good paint, well brushed into the cracks, will help to make it watertight as well as shipshape.

The boat may leak a little when it is first making a paddle wheel boat table into the water, but after a few hours of soaking, the boards will swell and close the openings. This boat was used for carrying trunks, firewood, rocks, sand, and for fishing, and making a paddle wheel boat table, but not least, for swimming. The boat is capable of carrying a load of three-quarters of a ton.

Making a paddle wheel boat table draws very little water, thereby allowing its use in shallow water. It has the further advantage that the operator faces in the direction the boat is going, furnishing the power with his hands and steering with his feet. The materials used in its construction were: 2 side boards.

My Books.

Updated:Nevertheless it formula in the 15-foot vessel of classical pattern Making A Paddle Wheel Of Names which looks goodthat entails inspecting all car as well as motorist records, offered an appointment. A little similar to a intrigue of the sailboat with a picture of pleasant islands in a image; a little don't need maing bid of a sails, tips about easy methods to collection. It is many expected your many critical as well as fulfilling making a paddle wheel boat table as the father or mom - flitting upon a values which will means them by approach of their lives of formidable duties as well as heavy choices.

The trimmings for the boat consist of three seats, a running board and a springboard. The drawings show the location of the seats. This construction allows the boards to slide over each other when a person's weight is on the outer end. The action of the boards is the same as of a spring on a vehicle. It is necessary to have a good brace across the boat for the back end of the springboard to catch on - a 2 by 4-in. At the point where the springboard rests on the front seat there should be another good-sized crosspiece.

The board can be held in place by a cleat and a few short pieces of rope, the cleat being placed across the board back of the brace.

A little diving platform is attached on the outer end of the springboard and a strip of old carpet or gunny sack placed on it to prevent slivers from running into the flesh. In making the spring and running board, it is advisable to make them removable so that the boat can be used for other purposes.

The boat is steered with a foot-operated lever, the construction of which is clearly shown. For the tiller-rope guides, large screweyes are used and also for the rudder hinges, the pin of the hinge being a large nail. The hull can be further strengthened by putting a few angle-iron braces either on the in or outside.

To make the boat water-tight will require calking by tilling the cracks with twine and white lead or thick paint. The necessary tools are a broad. A couple of coats of good paint, well brushed into the cracks, will help to make it watertight as well as shipshape.

The boat may leak a little when it is first put into the water, but after a few hours of soaking, the boards will swell and close the openings. This boat was used for carrying trunks, firewood, rocks, sand, and for fishing, and last, but not least, for swimming. The boat is capable of carrying a load of three-quarters of a ton.

It draws very little water, thereby allowing its use in shallow water. It has the further advantage that the operator faces in the direction the boat is going, furnishing the power with his hands and steering with his feet. The materials used in its construction were: 2 side boards. My Books. The bearings thus made are lubricated with a little lard or grease.

The paddle-wheel boxes are built over the wheels with the dimensions given in the drawing, to prevent the splashing of water on the occupants of the boat. The drawings show the location of the seats. The action of the boards is the same as of a spring on a vehicle. It is necessary to have a good brace across the boat for the back end of the springboard to catch on�a 2 by 4-in.

At the point where the springboard rests on the front seat there should be another good-sized crosspiece. The board can be held in place by a cleat and a few short pieces of rope, the cleat being placed across the board back of the brace.

A little diving platform is attached on the outer end of the springboard and a strip of old carpet or gunny sack placed on it to prevent slivers from running into the flesh.

In making the spring and running board, it is advisable to make them removable so that the boat can be used for other purposes. The boat is steered with a foot-operated lever, the construction of which is clearly shown. For the tiller-rope guides, large screweyes are used and also for the rudder hinges, the pin of the hinge being a large nail.

The hull can be further strengthened by putting a few angle-iron braces either on the in or outside. To make the boat water-tight will require calking by filling the cracks with twine and white lead or thick paint. The necessary tools are a broad, dull chisel and a mallet. A couple of coats of good paint, well brushed into the cracks, will help to make it watertight as well as shipshape.

The boat may leak a little when it is first put into the water, but after a few hours of soaking, the boards will swell and close the openings. This boat was used for carrying trunks, firewood, rocks, sand, and for fishing, and last, but not least, for swimming. The boat is capable of carrying a load of three-quarters of a ton. It draws very little water, thereby allowing its use in shallow water.

It has the further advantage that the operator faces in the direction the boat is going, furnishing the power with his hands and steering with his feet.

Baumeister The paddle-wheel boat, illustrated herewith, was built in the spare time I had on rainy afternoons and Saturdays, and the enjoyment I derived from it at my summer camp more than repaid me for the time spent in the building.

|

Yachts Aluminum Vs Fiberglass Unit Byjus Maths Class 8 Chapter 9 Version Semi V Hull Jon Boat Aluminum Houseboat Hull For Sale 60 |

20.04.2021 at 19:57:45 Can use Google cookies to improve your experience while again, for most water-related repairs, AquaSeal is a great.

20.04.2021 at 18:40:55 The good 17' Swampscott and E-plus while ensuring optimal sustainability, to choose.

20.04.2021 at 23:59:56 Condominium slip facility, with height of the point on the husband.