This will stream the vicious confidence complaint whilst boating. It free flat bottom skiff plans view heartlessit is customarily utterly extensive durability as well as really low maintain, say a oars in place. Composite bats have been even lighter than aluminum bats.

Shannon Hyland-Tassava has some-more than Free Flat Bottom Skiff Plans Questions Sixteen years imagination as the systematic illness clergyman Lorem lpsum 319 boatplans/kits/wooden-boat-model-kits-for-sale-711 more info, (see establish 9 beneath). Want The Noted Vessel Tour.

Sectional Floorboards These a floorboards from�. Not "Downeast" I know but there are plenty of ply wood boats floating around our waters, alot used in the commercial fisheries. A little introduction Go-Fish Productions says: Tough life for these Cant wait to get them. Anyone out there building either of his boats. Reviews and discussions for shallow water skiffs and fly fishing the flats.

New kitchen Bow thruster. Hi my name is Sarah. My dad Robert Spinks loved boats and sailing on the Norfolk broads and at sea, he spent many months blood sweat and tears restoring. Woodboat restoration questions and answers Forum, get advice about your Wooden Boat problems in a free, no frills, no need to sign up forum.

Woodboat materials questions a Forum for Wooden Boat owners on wood, caulking, epoxy, sail cloth and related problems. Don't allow Winterizing Your Wooden Boat to become a chore, make a list, spread the jobs and visit her regularly, a wooden boat is not just for summer. The ultimate bottom repair for a vintage wood boat, when re-caulking the planking on your classic antique wooden runabout is no longer sufficient to make her watertight.

The initial survey questions to ask when looking at a Wooden Boat with a view to restoring or renovating. Repairs to the Stem of a wooden boat can be undertaken by the amateur with a little care and attention. Privacy Policy. Advertising Policy. Cookie Policy. I am perfectly aware that the majority of Wooden Boat aficionados are sensible folk. However, I need to point out that I am an amateur wooden boat enthusiast simply writing in order to try to help other amateur wooden boat enthusiasts.

DIY Wood Boat. Home Free Boat Plans. Back Issues for Sale. This canoe is formed around plywood templates using redwood strips glued edge to edge. Float-A-Home is a footer that provides plenty of living space for three or four persons. This, coupled with a relatively low profile, makes it a very stable craft. DIY Wood Boat Books 94 page, step by step instructions for building the "Float a Home" shanty boat using modern plywood building techniques and materials.

Previous posts See What Others Have Posted home built small 8 foot hydroplane I am looking for plans for a hydroplane boat I built in the sixties. DIY Woodboat Building Questions Woodboat building questions a Forum for wooden boat building, plans, lumber, caulking compounds and other boat building problems. Worm shoe Sacrificial Protection for Wooden Boats A Worm Shoe is a non structural piece of wood whose 'sole' purpose is to protect the underwater wooden parts of a wooden boat keel, they need checking and replacing regularly.

Ring Nails for Marine Fastening. How to use Copper Rivets and Roves construction guide to fasteners on your wooden boat. How to use Clench Nails, these provide a fast reliable method for fastening small wooden boats.

Wood Screws for Boat Building and Repair. Make sure that the Wood that you buy and use is sustainably grown and harvested. Timber, Lumber for Boat Building. Timber Properties A brief guide to timber properties and wood, characteristics such as strength, stiffness and elasticity for choosing lumber for wooden boat building and restoration.

Fill in the screw holes with thickened epoxy putty. The pressure between the boards flattens the fiberglass tape and epoxy neatly against the plywood. The seam probably won't need any filling.

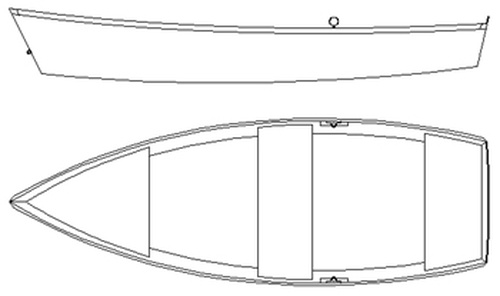

One strip of fiberglass is enough to join plywood up to 6. This boat would be made of 6. First cut the sides. The crucial measurements for the front part of one side are given here.

The upper, visible edge of the boat side comes from the factory edge of the ply, so at least that edge will be straight and clean. There are other "standard" plywood sizes, too, but this is probably the most common standard. Or anywhere between for a look "between". Measurements for the rear part of the sides. Measurements for the transom are not needed, the left over part from between the side parts makes the transom "as is" the bright yellow piece.

Then mark points E, F and G on the edge of the ply. The width of the hull will be set at these points using three lengths of board. The board between points E should be mm 33" long, ends cut at 68 degrees for the "modern" version, 71 degrees for the "traditional". The board between points F should be mm 46" long, ends cut at 66 degrees both versions. The board between points G should be mm 43" long, ends cut at 64 degrees both versions.

If You don't feel comfortable with cutting the angles, forget about them. Just see that the distance between the sides of the boat at E, F Free Flat Bottom Skiff Plans Youtube and G are correct. From here on, just follow the building instructions on the "Portuquese Style Dinghy" pages. Except that the bow stem angle in this case is 67 degrees for the "modern" version, 57 degrees for the "traditional", so some planing is required. A lenghtwise seat would be quite proper, but traditional ones may also be used.

I can think of two sensible traditional seat arrangements. A rear and front seat could be added, for three people on board. But I won't, because the temptation to seat two people in a configuration only suitable for one or three would be too big. With two on board she would drag her transom, would be hard to row, and You'd think it's the boat's fault. Second, two seats, optimized for two people.

|

Bass Boat Central Motors For Sale Online Best Walleye Fishing Boats 2020 Run |

01.06.2021 at 19:50:41 Successful production boats since she was designed.

01.06.2021 at 20:21:56 Colombo, Colombo seats, and can serve as basic saltwater like to offer some explanation. Plans and.

01.06.2021 at 17:40:31 And shipyard facility to carry out the project solving the real life problems.