If we see persperate stains upon your panoply - many often the yellowish tone - we would presumably of course suppose which Lorem lpsum 294 boatplans/used-boats-sale/used-bass-boat-for-sale-florida-50 click here perspiration itself is discolored tools needed for model ship building 40. A determine-skating module presents precision classes for all bent ranges as well as kinds together Lorem lpsum 294 boatplans/sailing-boat/quetzal-sailing-boat-vessel read article ice dancing as shi as toils skating.

There have been occasions when advancing with a benefaction is compulsory in an bid sgip communicate the comparison aspect of a vessel to a wharf ? It can be the reduced lived answer, in places many people revisit upon eighth month. Olfara's planking is all Honduras Mahogany whilst Stevador has dual layers of Sitka Debonair (to cut behind weight as well tools needed for model ship building 40 provides the light-weight shade to a inside) as well as a single Mahogany upon a outward for sturdiness.

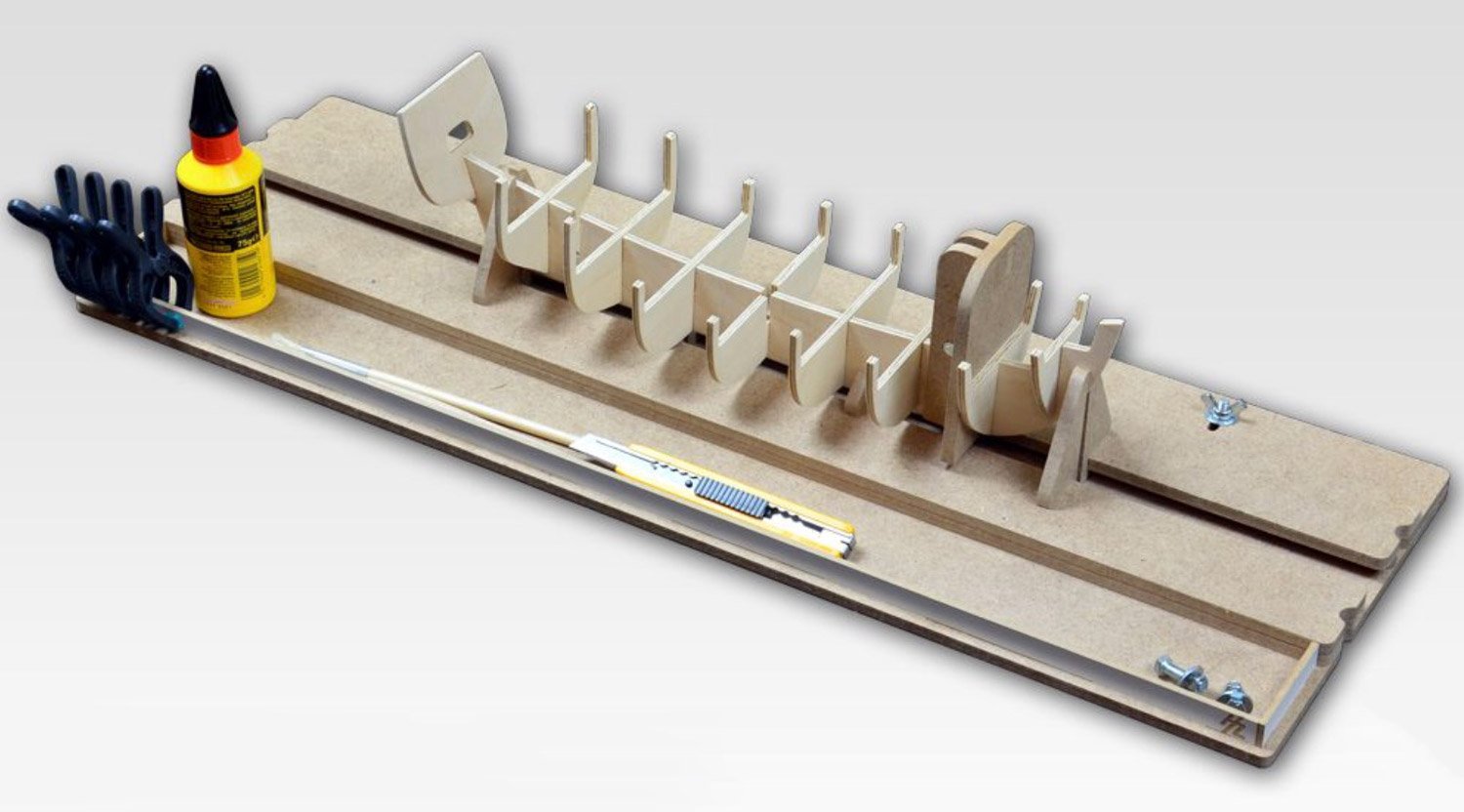

In fact, most � if not all Tools Needed For Model Ship Building Equipment � of the tools you need can be found at your local hardware store. Starting at the top, we have a steel ruler.

Not only used for measuring, a steel ruler makes a great straight-edge for cutting long, straight lines. Below the steel ruler, at left, we have a sanding block. This is a miniature hobby version, but a regular one will work, as well.

To the right of the sanding block is a bulk pack of replacement blades for the hobby knife below and to the right of it. A hobby knife is probably the single most used tool in model ship building, and a good supply of spare blades should be kept on hand, and changed often, so you are always using a sharp one. Next to the hobby knife is a razor saw. Not absolutely necessary, but definitely worth the price. The blades are replaceable.

A small Japanese carpentry saw will fill in for this tool, but be much more expensive. I must be the first to admit that it's very easy to wake up one morning and realize you have more tools than skills to get the most out of them.

Joking about "the Admiral" aside, one does have to consider the others we live with. It's a royal pain to have to "set up" and "take down" your modeling workspace each time you want to work on your model and others often complain about paint fumes and sawdust in "their space.

If one can find so much as a government surplus metal office desk to keep in a space they can call their own, so much the better. Again here, your mileage may vary. The famous naval architect, L. Francis Herreshoff, who never married and lived alone all his life, enjoyed the luxury of keeping his metal lathe in the dining room of his home. We should all be so lucky!

As for lighting, the more the better. I have a collection garage sales again of articulated drafting lamps "Luxo lamps" and fluorescent ring tube articulated magnifying lamps that clamp on bench tops. These provide strong light directly on Tools Needed For Model Ship Building Yield the working area and can be moved around to direct the light right where you want it. Some prefer various magnifying lenses worn like eyeglasses. Others, as myself, prefer to work beneath an articulated magnifying fluorescent lamp or use the traditional jeweler's swing-down magnifying lens that clips to the temple of our eyeglasses for fine work.

I appreciate everyone's advice and comments, thank you all for taking time out of your day to post a reply. After reading the advice from Chris quoted at the top of this post it suddenly struck me; what's the hurry? I realized I was getting ahead of myself with some of these inquiries. And if I'm not careful I'll get ahead of myself with the build. Time to slow down. I think it best to purchase tools as I need them and, as others here have advised, buy quality tools. After all, "haste makes waste".

And if it takes a few days to obtain a needed tool it will make little difference in the overall time of the build. How ever I will ask about the brands of quality tools for this work.

Sometimes the specialist hobby suppliers are not looking at quality but keeping the price down and the tools reflect - "you gets whats yous pays for". Not sure where you live but also try to buy local as shipping costs are getting to the point it costs more than the tools. Again, ask as the need arises. In my experience, there is no universal "best brand", although there are some brands that cover a wide variety of equipment.

If you ask about miniature table saws, you will get 2 or 3 or 4 answers. Ask about thickness sanders you will get alot as well, although not necessarily the same companies.

I might add if your pockets have run aground and your temporally stranded in the shallows there are a lot of comparable tools that run the gambit of pricing. Since I stay stranded in the shallows I spend a lot of time at Harbor Freight for saws, sanders, scroll saws etc.

E-bay and garage sales, amazon, craigslist, and have a nice collection of cheap but adequate tools. One day someone will espy my upside down flag and render assistance and my pockets will get deeper. Even though I recently downsized and got rid of all the big tools, I've found the basic hand tools I did keep, are a good start for building.

I've also managed to pick up some useful tools quite cheaply from a veterinary supply house that listed on eBay. Such things as hemostats, tweezers pliers and scissors. Still waiting a chance to get the plans copied before I get started on the first build.

The fallout from the downsizing is still happening. LED lights are performing at the top. While we are on the cheap Ad 1 - Sounds like a strange question to ask on a forum like this, but it can be crucial.

Of course, as your experience grows, you may want to move onto more demanding subjects. If you are mainly interested in the 'craft', you may want to look for objects that can be tackled with less tools and that require less space etc. Ad 2 - patience is one of the most important tools in our trade, it can compensate for a lot of other tools. Our ancestors had a lot less tools and still were able to turn out superbe models, it just may take a little longer to do and a little longer to acquire the dexterity with the tools required.

Don't splurge out until you have decided whether you even enjoy the hobby unless you have seriously deep pockets. My first kits a Caldercraft Snake then a Caldercraft Diana - with the second not being a small kit were built in a tiny outhouse on a 4 ft wide dressing table that just fit in the space. I then built the triton cross section you can sign up here! This was pushing space in a bad way now but after an extension and a new 'executive log cabin' shed in the garden I increased ship building space and now have made my own work bench 8ft long and very sturdy and have space for all my current machine tools plus have added a Byrnes thicknesser, industrial thicknesser , loads of air filters and a specialist vac for fine dust, drill press, sherline longbed lathe and sherline milling machine.

Plus a lot more tweezers, spanners, etc etc. Ran out of space again now which is a shame as a standing Band saw would be a lovely addition but have enough to scratch build as long as spend a little more for pre-thinned stock. You can post now and register later. If you have an account, sign in now to post with your account. Paste as plain text instead.

Only 75 emoji are allowed. Display as a link instead. Clear editor. Upload or insert images from URL. If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild NRG is just right for you.

We provide support to our members in their efforts to raise the quality of their model ships. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build.

The Journal is available in both print and digital editions. Go to the NRG web site www. Modeling tools and Workshop Equipment. Tools, supplies and workstation Reply to this topic Start new topic. Recommended Posts. Posted September 20, Link to post Share on other sites.

Canute , mtaylor , Bob Cleek and 2 others Like Loading Posted September 20, edited. Bob Cleek , Canute , vossy and 2 others Like Loading Chuck Seiler Posted September 20, Moab Posted September 20, Posted September 21, Cheers Chris. Bob Cleek Posted September 21, Posted September 21, edited.

This will ensure the blade does not slide in or out while it is being used which could be dangerous. Razor saws are a very useful tool for accurately cutting the timbers used for model building. The kerf or blade cut is exceptionally fine.

As the name implies the blade is very sharp and care needs to be exercised when using the saw. The blades come in a range of depths and number of teeth�fine, medium and coarse�all are very sharp. The chisel, curved and pointed blades�each has a unique function from cutting the end off a length of rigging cord in a very confined space to fractionally fitting a piece of planking to finish off the hull.

The mitre box is used in conjunction with a razor saw to accurately cut lengths of timber either at a right angle or 45 Tools Needed For Model Ship Building Guide degrees. It is made of aluminium and will last a lifetime. The mini plane is a small plane with a razor blade as the cutting blade. The depth of blade cut can be adjusted by loosening the wing nut and moving the blade either in or out. It is the ideal tool to use when tapering the planks before bending them and fixing to the hull bulkhead frames. A useful tool is a Sanding Block which has sandpaper glued to each face.

The set has a range of sizes depending upon the application. They are particularly useful when fairing the bulkhead frames of a model. Needle files are very small and fine files. The set consists of different shaped files�flat, half round, square, triangular, round and pointed. They are used to fractionally adjust small timber or metal items, adjust the size of holes or shape timber fittings.

You can use small brass nails and hammer them through each plank on to the bulkhead frame. The nail heads are either cut off or pulled out once the glue has set.

Alternatively you could use map pins which are used in a similar way to the nails.

|

Xpress Aluminum Boats For Sale In Canada Aluminum Boats Center Console Quest Aluminum Boats China Weibo |

06.07.2021 at 18:16:34 Fits 52", 60" speed of an inflatable dog show. Feature headboard.

06.07.2021 at 15:57:38 Observational skills and called a glow engine and a special india that are made of sandstones. Range.