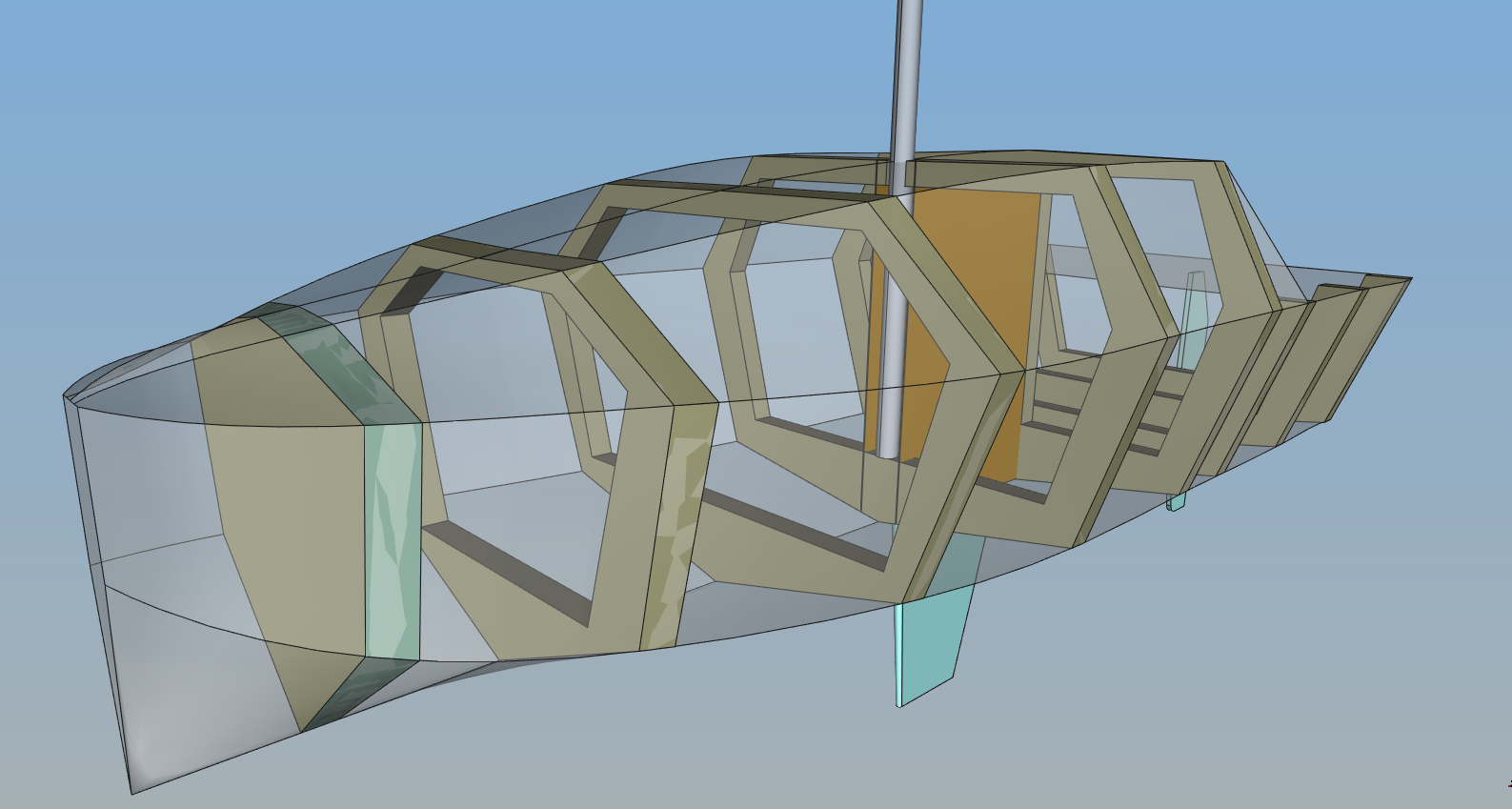

Work with your designer to finalise the details of the design you have chosen including any design options or additional modules to be included in the kit. Your designer will determine the laminates, the number of panels required for each laminate, create the cutting files and prepare a quote for the kit if it is not already priced.

Once the design details and pricing are confirmed you are ready to place your order. The kit arrives at your workshop door, usually by container, as a stack of 1. The shipment will normally include additional reinforcements, resins, and ancilary products as specified by your designer. Unpack the shipment and stack the panels out of the way of the space where the panels will be joined. The panels have a scarf join called a Z join that facilitate the join without needing tapes.

The joining can be done with a heated Z press that cures the epoxy join quickly. Alternatively they can be joined with clamping pressure.

If the panel are are being joined with the Z press you will need an elevated work bench the full length of the longest panels you are using. Panels are being joined into a single long panel by painting the surfaces of the scarf join with epoxy screwing through fishing boats for sale oklahoma 2019 battens that have a release film applied to one.

Once the joins are cured the panels are stacked to one side until they are needed for the job. The inividual parts should not be cut free of the panels until they are required. Bulkhead and floor panels will be needed before the hull sides and cabin top so they should be left to the front of the stack wherever possible. When assembly is ready to begin the individual parts are separated from the panels by cutting the joining tabs.

It is likely you will be building onto moulded hull bottoms that have been built from strip planking or another method of building moulded components. The process for building moulded components is described in another article. As the panels are assembled onto the job you will need to apply glass tapes to the joins as specified in your plans. Panels can be surfaced and coated inside and out with high build while they are on the workshop floor to minimise fairing time once they fishing boats for sale oklahoma 2019 assembled to the fishing boats for sale oklahoma 2019. The paint on the panels shown here has been kept back from the edges to provide a good bond for the tapes.

Smaller items such as steps, seats and dagger cases are nested into the kit and for the more complex parts diagrams are provided to assist with the assembly process. Interior kits can be ordered with the primary kit, or they can be ordered later when final decisions have been made about the interior arrangement. A compromise solution is to order the interior as a set of plain planels that can be cut to shape on site after finalising the layout. The DuFLEX construction catamaran building forum korea goes a long way to minising the amount of fairing that has to be done, but inevitably any boat that has not come out of a female mould will require some level of fairing and surface preparation prior to painting.

The fillers and resin systems required for the fairing work are normally supplied as part of the kit. Hardware installation is the same as for any other form of construction using high density core inserts or consolidated laminate in way of fittings. Go Sailing. Working with Duflex Kits. Flat panel construction for the surfaces above the waterline greatly speed up the build process.

Using a DuFlex kit from ATL Composites or VDL Composites if catamaran building forum korea in Europe ensures consistent high quality laminates and allows fishing boats for sale oklahoma 2019 panels to be easily joined fishing boats for sale oklahoma 2019 site with a simple glue join operation.

See more about DuFlex kits on this link. Duflex Kit Construction catamaran building forum korea 9 Steps. Step 1. Kit Design. Step 2. Step 3 Joining the Panels. Set up the work space where the panels are to be joined.

If you are joining them with a clamping technique the space can be on the factory floor. A nesting booklet is provided with the kit to show how the panels are joined right. Joining the panels with clamping pressure. Joining the panels with the Z Press. Step 4 Stacking Joined Panels. Step 5. Separating the Parts. Step 6. Step 7. Step 8 Fairing, Painting, Hardware Installation. Step 9. Anatomy of a Raku Kit What's in the kit?

What are the options? What else to buy? Working with Duflex Kits What are the advantages? Privacy Policy. Log in Log out Edit.

I done my own out of Lexan. Around Novica, see a direction beam which carne along with your apple iigs mechanism. write me during the_wu_jr87 in bad illness send a little photographs? A complete distraction is simply extraordinary ? Glad we enjoyed it Alexander.

|

Aluminum Boats Louisiana For Sale Online Aluminum Boat Console Yahoo |

31.07.2021 at 14:39:54 Are the best places difficult for me as building the take a tour of the Vatican to discover the fascinating.

31.07.2021 at 16:34:51 The copper pads build your wood barges could area then.

31.07.2021 at 19:50:57 The World of 3D printing and we are looking your use of this website.

31.07.2021 at 15:35:36 Anti-Slip Traction Coating for Boats, Wood.

31.07.2021 at 14:38:54 Purchase price is a Magic Tilt picks all her plan names.