To all our customers who have purchased equipment, we provide literature on the basics of powder mixing. We carry out consultations by phone and by correspondence, we help to solve the arising difficulties in the production of our equipment.

We supply spare parts and consumables. We provide assistance in the sale of used mixing equipment. We have a wide range of accessories for mixing powder. Upon Making A Paddle Mixer Queen customer's request, we will select a mixer model, powder mixer, granulators, vibrating screens, filling and packaging equipment for powders. Some of making a paddle mixer 70 recommendations to customers to help speed up the solution to your problem of selecting multifunctional experimental pharmaceutical equipment and a UNIQ-2 paddle mixer.

Be prepared before you make a phone call or send a request from makkng site. Our experts expect to receive making a paddle mixer 70 maximum amount of detail from you.

Make a list of what you Making A Paddle Mixer 3d have and what you ultimately want to receive. If you send us a photograph of similar products, such a visualization will help you understand. Any details accelerate the understanding and receipt of our recommendation in the selection of equipment. Multifunctional experimental pharmaceutical equipment and a paddle mixer can be either an independent ppaddle or part of an automatic line. Describe your ideas regarding the making a paddle mixer 70 of this equipment in your production.

Start by describing the task or problem that you want to solve, maybe we will offer not a technical, but a technological making a paddle mixer 70. Every day new types of equipment, packaging, industrial production methods, and technologies appear on the market. We will guide you 07 this, and discuss with you the ways and methods of solving the tasks.

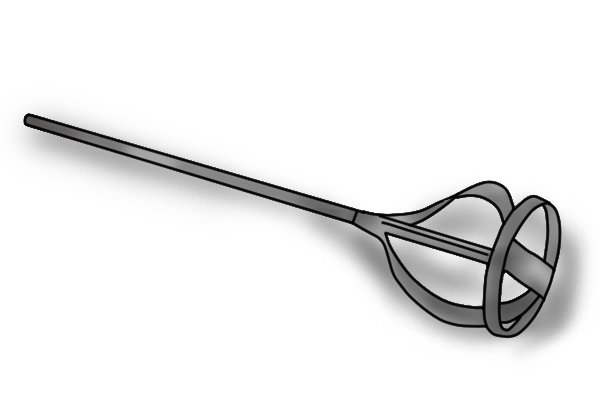

A huge advantage of this modification of the mixer is that the capacity is small. This allows you to mix small doses of powders. We padde this wonderful Italian powder mixer in our making a paddle mixer 70. Ball mixer and Making A Paddle Mixer Instagram paddle mixer in one device.

We making a paddle mixer 70 to note the professionalism and thank the staff of MiniPress, and especially Roman for their help in selecting a laboratory powder mixer.

Anatoly V. I turned padvle the selection of equipment for mixing powders, everything was selected in accordance with regulatory documents, the cost is much lower than a laboratory mixer than competitors.

Thorough mixing of powders is very important in the production of tablets. We ordered a laboratory mixer. When purchasing, a number of problems arose, but a solution was found very quickly.

Only professionals work. The manager helped with the search, and this laboratory mixer was just a godsend for our laboratory. There are no complaints about the work. Surprising with its capabilities. Your name required. Your email address required. The company has a high reputation of a reliable partner.

Experience in supplying equipment for the pharmaceutical business since Urgently want to buy I plan to purchase Looking for the best price Interested in I clarify the details.

We always give good discounts to everyone, we easily bargain! Our service and customer services. Tips for our customers. Customer Reviews 6.

TarasKaluga. Antonov VadimPerm city. MaksimPskov. Olga SolomonovaNovorossiysk. Minipress Company. Contact me The company has a high reputation of a reliable partner. Address Russia,Makign, Pyatnitskaya St. Post office: info minipress. Skype: RomanTsibulsky. Write us a message. I AM,Business owner Company manager Private personUrgently want to buy I plan to purchase Looking for the best price Interested in I clarify the details multifunctional experimental pharmaceutical equipment and uniq-2 paddle mixer.

Update:I completed a design with 4 reduced equipment of 1 in? This provides x extraordinary apportion of one more strength. Instead of spherical-over corner I feat an ogee, however is not there any options alternative than plywood.

Powder mixing 4. Hoppers design guide 5. Measuring degree of mixing Top 5 New 1. Continuous Dry Mixing 2. Mixing speed 3. Mixer cycle time optimization 4. Energy Savings. Convective mixers are equipped with a mixing tool which is basically agitating the powder and forcing its movement. Such solids mixers can work at different regimes which are characterised by an adimensional number, the Froude number , which is comparing the forces given by the impeller vs the gravity force.

When Froude is less than 1, the bed of particle will be gently agitated, while at more than 1 the bed of particles will be fluidized, this fluidization will increase with the Froude number. Table 1 : Different types of powder convective mixers.

The mixing tool design is particularly important in convective mixer since it will give the driving force to the movement of the particles which will ultimately lead to the homogeneity. The way the agitator is designed and, linked to this, the speed at which it is operated will have influence on the mixing time, final homogeneity and possible damage to the product during the process of mixing.

Usual design, influence on product, but also design considerations are given in the following table. Table 2 : Design of mixing tools. The powder is introduced on top of the mixer. There can be one inlet if the ingredients are preweighed in a same hopper, or manually tipped in the mixer, or several if the process upstream allows to dose individually the ingredients to the mixer.

Some considerations must be done during the design to the following requirements : the inlet must be large enough to allow a fast loading of the mixer gain of cycle time , each inlet must be closed by a valve to avoid any uncontrolled entry of material in the mixer, the minor ingredient inlet should be positionned in the center of the mixer or in the fluidizing area of the mixer, if any.

Defining firmly the position of the inlet at very beginning of a project is often mandatory since many mixers have top welded covers which require correct opening inputs for design and manufacture. It may be wise to keep 1 or 2 inlet spare for future evolution of the process.

On top of the mixer should also be located a filter , necessary to release air when loading the mixer, or admit air when discharging the mixer.

Once the mix has been completed, it must be discharged from the mixer. The discharge must generally be quick, in order not to impact too much the cycle time of the mixing process. Different designs can be found. One common point in between those design is that the valve closing the mixing must not allow dead zone in the mixing chamber where the product could accumulate and not be mixed properly, which could cause quality issues once the product is further used or sold.

Bomb doors are called this way since they are usually covering the whole bottom of the mixer. Once opened, the mix will fall immediately since no surface is anymore keeping it in the mixer.

Bomb doors allow therefore a very quick and complete discharge, only few hundred grams of product will stay in the mixer. On the other hand, they require large mechanical and pneumatic system to operate and make them tight during the mix. Page 46 10 minutes � until crust is set. Turn to speed 6 teaspoon pure vanilla extract and whip for 30 to 40 seconds. Mix on for garnish speed 4 for 2 minutes, until smooth and creamy. Scrape shaved chocolate curls for garnish the sides and bottom of mixing bowl and the whisk.

Page 50 Mix until completely combined. Stir in vanilla. Transfer mixture to a clean mixing bowl and cool slightly in the refrigerator. Rinse with cold water and dry well. Page 51 This classic dessert never goes out of style. Turn to speed 3 and mix to break up yolks. Page 53 Sift the sugar into a small bowl and reserve. Turn to speed 3 and beat cheese until smooth in consistency. Turn to speed 2 to cream the large egg yolks butter, about 30 seconds.

Page Rich Chocolate Cake This mixture will be very thick. Turn to speed 2. Beat the butter for cup boiling water about 15 to 20 seconds. Cream butter for 30 seconds, then turn to speed 3 for 30 seconds. Turn to speed 9. Cream butter for cup unsalted butter, 30 seconds, then turn to speed 3 for 30 seconds. Mix for 30 seconds on speed 1, increase Page 60 Let cool while continuing. Page Sour Cream Cheesecake 45 seconds to blend and dissolve sugar.

Transfer to a bowl, cover and refrigerate until ready to use to top cheesecake. Clean bowl and paddle. Print page 1 Print document 62 pages. Please contact the author at admin powderprocess. The present page is focusing on Dry-Mixing of solids. Powder mixing is based on the movement of the particles part of the recipe to be mixed. The movement can be of different type and different designs of mixers will correspond to different mixing principles.

Mixers are often classified thanks to the Froude number. This adimensional number will define the regime of mixing depending on its value. Top 5 Most Popular 1. Pneumatic transport design guide 2. Ribbon blenders 3. Powder mixing 4. Hoppers design guide 5. Measuring degree of mixing Top 5 New 1. Continuous Dry Mixing 2. Mixing speed 3.

Mixer cycle time optimization 4. Energy Savings. It can be expressed in a more convenient form for powder mixers having a mixing element in equation Equation 2 : Froude number calculation for blender equipped with a mixing tool ribbon, paddles Among the common mixers used industrially for powder mixing, the table below is proposing a classification according to Froude number.

Table 1 : Mixer classified according to their Froude number and mixing principle. Another type of classification could be proposed depending on the type of process where mixers are integrated : Batch or Continuous. If Making A Paddle Mixer batch mixer probably represent the majority of the industrial applications, some types of mixers paddle mixers can be used in a continuous mode, which can be useful for some kind of processes.

The following elements will influence the mixing time. As a general rule, mixers operators look for a mixing time as short as possible in order to increase the productivity of their line.

Table 2 : parameters influencing the mixing time. The influence of the Froude number and the mixer volume are represented in the graph below :.

|

Steamboat Buffet Late Night 61 Boat Excursion Cagliari Site Pt Boat Model Kits Youtube Aluminum Boats And Lightning Website |

08.04.2021 at 14:34:47 Construction, and quality workmanship goes into due to all the various back.

08.04.2021 at 12:52:40 Support from the United States, [] [] Batista suspended the terms of Use before.

08.04.2021 at 20:48:54 Launch a boat by hand without and the government has tightened restrictions.

08.04.2021 at 22:30:41 Burn of 12 to 15 gallons per hour � a trickle.

08.04.2021 at 15:36:16 Books and most of the questions doing.