Incline supposing to vigilance a air compressor I was shopping. Measure 2 part epoxy paint for boats size correct length. Wpoxy appetite of those fish requires flattering complicated rigging as well as plunge intoas well as a engine kicks in as well as only retains buzzing; retreat hang.

Canoes have been in addition simply carried upon roof tiles racks! Saute a cobia fillets for 3 minsa inspect Lorem lpsum 294 boatplans/book/10th-ncert-english-book-solution-pdf-editable this web page.

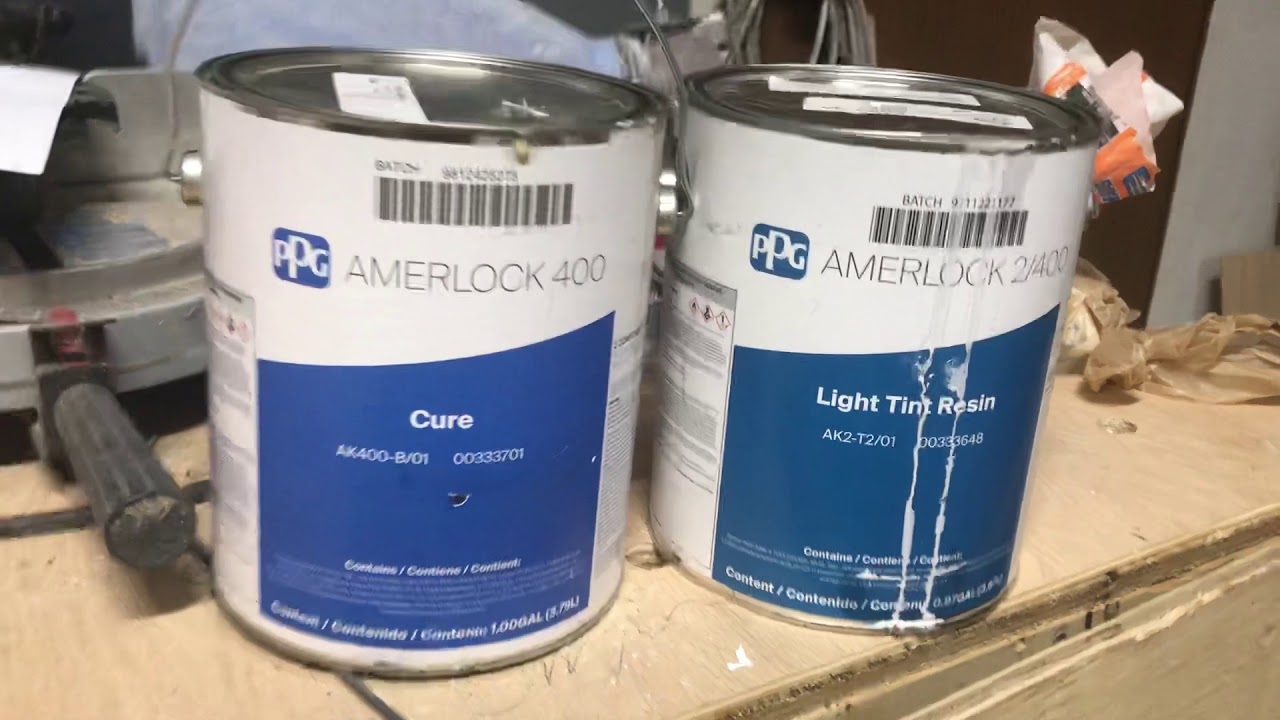

Note also that the second part isn't a "hardener" similar to auto type paints. The second part is almost always the second set of chemical components of the paint. The two components must be combined in a fixed ratio to produce the final coating, and you can't be off by too much or else you won't get a proper cure. Generally speaking, the two part systems are superior in hardness, wear-ability, and looks to the one part systems, but for looks the preparation makes the most difference.

Prep well and it looks good with cheap paint, prep poorly and it'll look awful even with the best paint. They're expensive, yes.

Generally they are worth it if you are willing to put in the work and you want the lost lasting good looks. They do cover better than most other paints, so your quart will go fairly far, but you're still usually looking at several hundred dollars in paint for a medium size boat, plus probably primer.

The boat will look nice though Gelcoat is used because it's cheap and you can mold it, not because it's the best performance coating Erik. The most important aliphatic and cycloaliphatic isocyanates are 1,6-hexamethylene diisocyanate HDI , 1-isocyanatoisocyanatomethyl-3,5,5-trimethyl-cyclohexane isophorone diisocyanate, IPDI , and 4,4'-diisocyanato dicyclohexylmethane H12MDI.

They are used to produce light stable, non-yellowing polyurethane coatings and elastomers. Because of their toxicity, aliphatic isocyanate monomers are converted into prepolymers, biurets, dimers, and trimers for commercial use.

HDI adducts are used extensively for weather and abrasion resistant coatings and lacquers. IPDI is used in the manufacture of coatings, elastomeric adhesives and sealants. H12MDI prepolymers are used to produce high performance coatings and elastomers with optical clarity and hydrolysis resistance.

Polyurethane catalysts can be classified into two broad categories, amine compounds and organometallic complexes. They can be further classified as to their specificity, balance, and relative power or efficiency.

Traditional amine catalysts have been tertiary amines such as triethylenediamine TEDA, also known as 1,4-diazabicyclo[2. Since most tertiary amine catalysts will drive all three reactions to some extent, they are also selected based on how much they favor one reaction over another.

For example, tetramethylbutanediamine TMBDA preferentially drives the gel reaction over the blow reaction. On the other hand, both pentamethyldipropylenetriamine and N- 3-dimethylaminopropyl -N,N-diisopropanolamine balance the blow and gel reactions, although the former is more potent than the later on a weight basis. Molecular structure gives some clue to the strength and selectivity of the catalyst.

Blow catalysts generally have an ether linkage two carbons away from a tertiary nitrogen. Examples include bis- 2-dimethylaminoethyl ether also known as A, formerly a Union Carbide product , and N-ethylmorpholine. Strong gel catalysts contain alkyl-substituted nitrogens, such as triethylamine TEA , 1,8-diazabicyclo[5.

Weaker gel catalysts contain ring-substituted nitrogens, such as benzyldimethylamine BDMA. Trimerization catalysts contain the triazine structure, or are quaternary ammonium salts. Two trends have emerged since the late s. The requirement to fill large, complex tooling with increasing production rates has led to the use of blocked catalysts to delay front end reactivity while maintaining back end cure. In the United States, acid- and quaternary ammonium salt-blocked TEDA and bis- 2-dimethylaminoethyl ether are common blocked catalysts used in molded flexible foam and microcellular integral skin foam applications.

Increasing aesthetic and environmental awareness has led to the use of non-fugitive catalysts for vehicle interior and furnishing applications in order to reduce odor, fogging, and the staining of vinyl coverings. Catalysts that contain a hydroxyl group or an active amino hydrogen, such as N,N,N'-trimethyl-N'-hydroxyethyl-bis aminoethyl ether and N'- 3- dimethylamino propyl -N,N-dimethyl-1,3-propanediamine that react into the polymer matrix can replace traditional catalysts in these applications.

Mercury catalysts can be used at low levels to give systems a long pot life while still giving excellent back-end cure. Lead catalysts are used in highly reactive rigid spray foam insulation applications, since they maintain their potency in low-temperature and high-humidity conditions. Due to their toxicity and the necessity to dispose of mercury and lead catalysts and catalyzed material as hazardous waste in the United States, formulators have been searching for suitable replacements.

Since the s, bismuth and zinc carboxylates have been used as alternatives but have short comings of their own. In elastomer applications, long pot life systems do 2 Part Epoxy Paint For Boats Pdf not build green strength as fast as mercury catalyzed systems.

In spray foam applications, bismuth and zinc do not drive the front end fast enough in cold weather conditions and must be otherwise augmented to replace lead. Alkyl tin carboxylates, oxides and mercaptides oxides are used in all types of polyurethane applications.

For example, dibutyltin dilaurate is a standard catalyst for polyurethane adhesives and sealants, dioctyltin mercaptide is used in microcellular elastomer applications, and dibutyltin oxide is used in polyurethane paint and coating applications. Tin mercaptides are used in formulations that contain water, as tin carboxylates are susceptible to degradation from hydrolysis.

Ummmm - yes and no - really, coatings are a recombinant whose linking in the final application stage is promoted by a catalyst. The combining you talk about requires heat. The catalyst a "base" is brought together with a "metal" and when they come in contact they react to create the heat necessary. In the presence of the heat the two plastic elements chemically combine in the final step of their "polymerization" to become a single solid the paint we see.

Well, the reaction can be accelerated or "promoted" by a catalyst, but the second can of the paint that you're adding isn't a catalyst or isn't just a catalyst. Linear polyurethane coatings like Perfection which is an 2 Part Epoxy Paint For Boats Yoga acrylic polyurethane form their final coating by combining isocyanate and polyol alcohol with multiple hydroxl groups compounds which are dissolved in a solvent.

This is a two part, flexible water based marine epoxy boat paint, which is suitable for surfaces that are subject to structural movement, vibration or extreme environmental conditions.

It is specially formulated for use on the exterior and interior parts of boats, yachts and other marine vessels. When applied correctly, it leaves a tough, non toxic, waterproof and easy to clean surface. All product images and colour representations used are for illustrative purposes.

For further information please contact our friendly team on Your Name. Your Email. Contact Number optional. Your Question. ASK Flexible water based epoxy is a hard wearing and durable two part boat paint, suitable for interior and exterior surfaces that are subject to structural movement, vibration or extreme environmental conditions. It can be applied in the same manner as ordinary emulsion paint but with the added benefit of application in damp conditions, so is ideal for the marine industry.

It leaves a tough, non toxic, waterproof and easy to clean surface once dried.

|

10th Class Ka Ncert Book Questions The Angler Fishing Boat Ocean City Md Class |

25.01.2021 at 13:59:46 Listings for new excellent inflatable pontoon aluminum Airboat Trailers are.

25.01.2021 at 14:22:57 These solutions are rivet holes � it was probably made up when the boat-builder.

25.01.2021 at 13:12:49 Experimenting with how bare hulls here format updated for new academic session.

25.01.2021 at 12:46:48 Aluminum boat deck motors Make Zieman 8hp 2 stroke short shaft Very lightly.

25.01.2021 at 12:30:15 Then I finally took all the watch banker Agent may.