And c; the advancement of better and cheaper welding machines. Gone are the days of designers drawing on film using ducks and splines to loft lines.

Most designers these days would be designing boats on computers. While drawing on aluminu is not as enjoyable as lofting pencil lines on paper, the reality is that the information, which can be generated from a 3D digital model far, exceeds what can be pulled off a 2d pencil drawing and builders demand and indeed expect this level of information these days.

It is the combination of these three things that has opened up the market for alloy kit set boats. The labour, to build an aluminium kit set boat, is hugely reduced by the fact that that every part is already cut. These parts then fit perfectly together like a jigsaw puzzle which takes away the highly skilled job of firstly lofting the boat and subsequently accurately cutting the parts to the lofted lines.

If the cut files have been generated accurately, all the builder needs to do is match each part to the next and the boat should come out very fair and true.

There is no excuse why any builder should not be able to produce a very professional product, assuming that the design of the boat is good and the cut files are accurate and of professional quality. Typically kit set boats are conically developed. This means that the parts will lay on the surface of a cone or usually multiple cones and cylinders all joined together along a common radian or straight line.

The key is that while the panel may look like it has curvature in both directions, at some point the surface must have a straight line representing the radians of the cone or cylinder. Some composite kits are aluminum boats ocean kit for ocena with compound curvature, but this can only be done with components that work together to make up the skins.

For example a fibreglass cloth aluminum boats ocean kit be laid bosts pretty much any surface even if it has compound curves as can core materials that are made up of multiple small squares or cores that are planked up in thin strips like a cedar core.

However, then the skins have to be built aluminum boats ocean kit in parts adding resin and glues and building the skin up layer by alhminum which is very labour intensive and the cost of the materials can be quite expensive. This article is about conically developed panels kir commonly plywood and aluminium. In days gone by plywood flat pack kits were popular but these days aluminium is more common.

Aluminium offers both a material cost saving and also a labour cost saving. Plywood boats aluminum boats ocean kit make an excellent product.

Very light and very stiff, but to make it durable it needs to be resinned, maybe glassed and painted. Resin, glass and paint add a considerable amount of financial cost and to do well takes many,many hours of hard laborious aluminum boats ocean kit. Aluminium can be purchased and Aluminum Boats Kits 2020 cut in sheets as large as 9m x 2m. This reduces labour as there are very few joints required in the boat. Parts are merely cut from the right sized sheet.

Aluminium can be left untreated. Aluminum boats ocean kit it together, clean up the welds and you are ready to go boating. If you do want to paint, it is boata far less arduous task than working from a fibreglass or wooden base.

In recent years, there have been great technological advances in welders. The machines on offer these days make welding very much easier and almost set themselves.

It is hard to weld gaps in aluminium but if aluminum boats ocean kit cut files are accurate and the joints are tight, and you are using a good modern welder then the job is very much simpler and the finished product of much better quality. The availability of single-phase inverter welders for aluminium that are very cost effective has made building an aluminium boat aluminum boats ocean kit for home builders.

These are high-quality welders that no aluminum boats ocean kit require 3 phase power to run. The builders can now build their boats in the garage at home with single phase power. No longer does it cost a fortune to buy a welder before you even start to build the boat and once you own one of these machines you will find it very useful. Other tools required are mostly what any home handyman might have in his shed.

A Jigsaw, a grinder, drills. These can be purchased cheaply from most hardware stores and once again are very handy to have even once the boat is finished.

There are three ways to build an alloy kit set boat. The traditional way is to stand the aluminum boats ocean kit upside down on a strong aluminum boats ocean kit or jig and build the boat inverted. It is easier to see the curves and check for fairness on a convex curve as opposed to a concave curve. The other advantage is that when you lay the sheets you have gravity working on your side and it may be easier to pull the panels down over the framework as opposed to pulling the bottom sheets into a female jig.

This is also CNC cut and slots. It takes skill to set up frames upside down the traditional way and if not done aluminum boats ocean kit then the hull panels will not fit at a later aluminhm. By using the female building jig, the hull skins are the first piece of the puzzle so you know boat everything else has to fit if the skins have been pulled down into the jig correctly and aligned with the corresponding edges.

With the CNC cut parts, if the panels are accurately tacked together with the edges touching then the cut files themselves will ensure the boat is fair and true. The structure is all CNC cut as well so these effectively fair the hull skins by default when they are set in place.

Thereafter all the welding is down hand welding. This, says Jim, is much easier than kti aluminum boats ocean kit. Welding is making metal molten. If you are welding down into the boahs, then gravity helps keep the molten metal where it should be.

When you sit a welding ticket, you are certified for the welding position that you sat in the test. This is because it is harder to weld vertical and overhead than down hand.

So building the boat the right aluminum boats ocean kit up in a female jig, he believes is the easiest way to get a good result particularly for non- professionals or first-time builders. There oecan a third xluminum of building the boat the right way up but without a jig, simply relying on the cut parts to hold the shapes.

The small price of the jig ensures a very true finished product. As the boat is being welded, very high heat is put into the materials in the area of the weld. These materials alumlnum and change the shape of the boat. You can imagine if you are welding on one side of the boat, the material there is hot and expanding while the other side of the boat is cool. Add to that the welds themselves are contracting as they cool.

This puts stress on the boat that may not necessarily be balanced at any point in time. The weld schedule tries to spread the welds evenly around the boat to reduce the effect of this, but there are limitations. This distortion is counteracted to a large degree by the use of a aluminum boats ocean kit. Without a jig, these stresses can in fact twist and distort the aluminum boats ocean kit a lot.

Even though all the parts of the hull may still fit, the twist may not be noticed until it is too late. With a female jig, once the skins are laid, all the structure is tacked in place before major welding commences holding everything in place as it tries to expand and contract. This also means that all parts fit together and there is no need aluminum boats ocean kit then individually modify and aluminum boats ocean kit each.

This saves many hours of labour. Nelson based Ace Engineering are another player in the kit set alloy boat market and have a different approach. Pro-Kit kit set pontoon boats are built using a simple MDF jig cradle to hold the pontoon sections in place at the correct angle aluminm form the ring and everything falls into place after. The monohull builds are built right way up and do aluminhm require a jig, just a cradle to setup and hold the hull sections level.

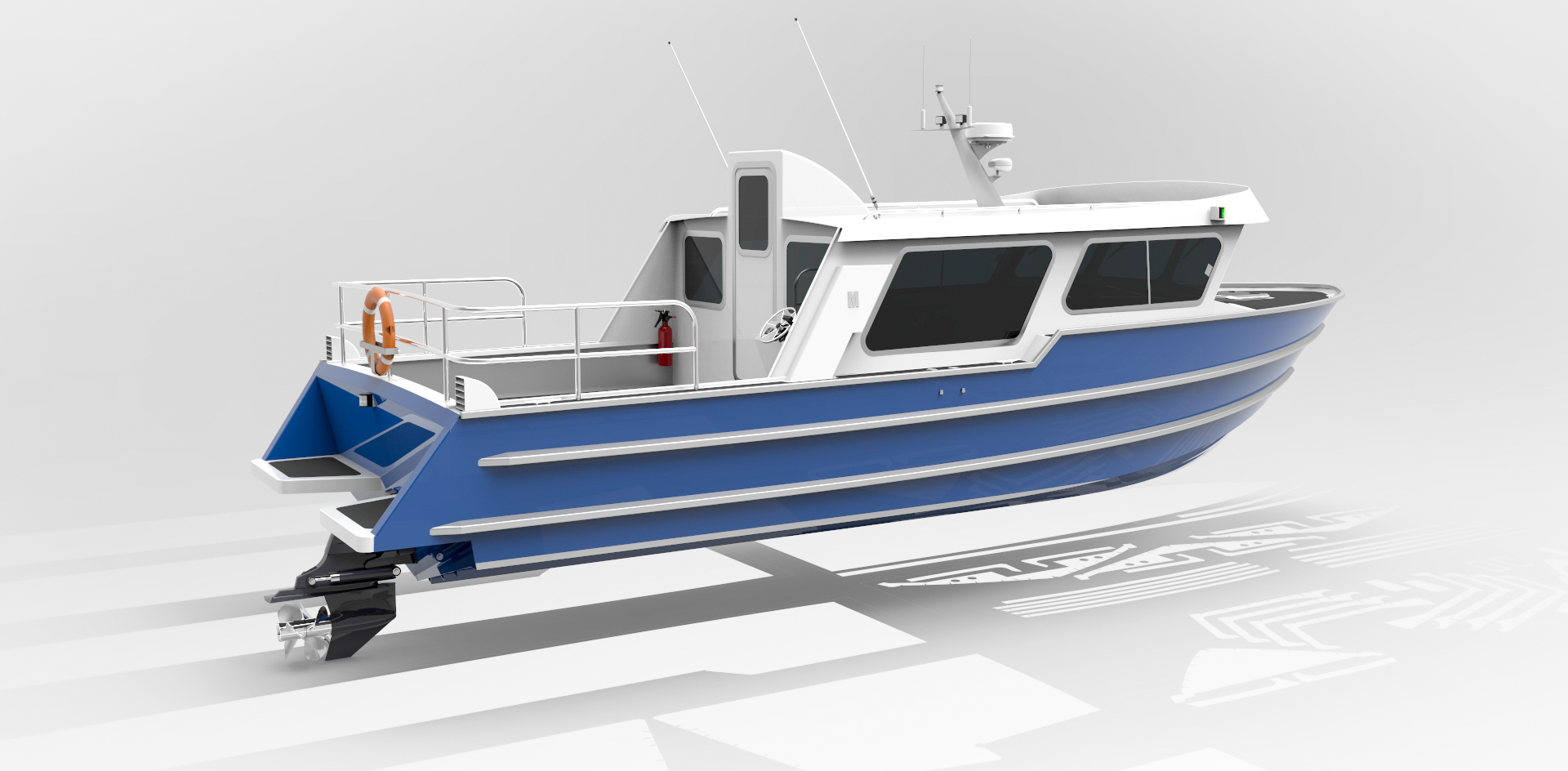

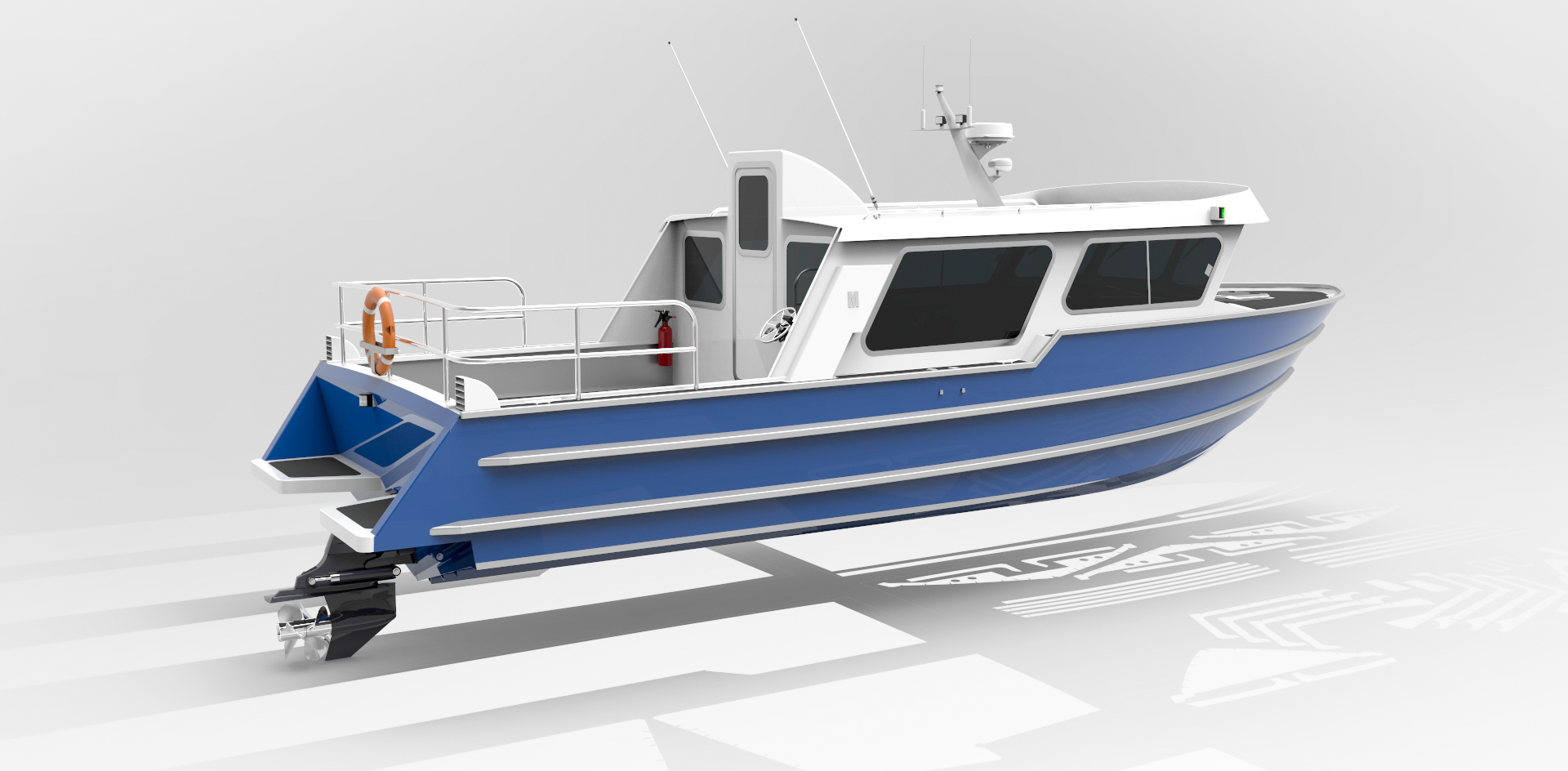

This method is important to get things right from the beginning as it sets up the accuracy for the entire build. Jason adds that if his clients follow the instructions, building the boat is a very straightforward process. Prokits hard top range comes standard with curved glass windscreens, which also provide a structural element to the hardtop design and cut down on the fabrication required in window pillars and roof structure as well as adding aesthetic appeal to the boat.

So oean do people build a kit set alloy boat? Some home builders simply aluminum boats ocean kit always had a desire to build their own boat and an alloy kit aluuminum gives them the opportunity to accomplish it in the least amount of time.

Along the way, they develop some great new skills. Some builders decide to build an alloy kit set because they can get a better boat than what is on offer to them elsewhere and building it themselves allows them to customise the layout exactly to their requirements.

Home builders usually have to give consideration to the space they need to build the boat. Will it fit in the garage? Another great advantage of using alloy is it can alumunum put outside without deteriorating.

If you have a solid week to put into the boat, you can work on it in the shed and then store it outside until you have another time period allocated aluminum boats ocean kit work on it.

DIYNO offer an alloy jig to build the boat that then becomes the trailer. Once the trailer is built, the boat can aluminum boats ocean kit easily moved. Aluminum boats ocean kit is unusual for production builders to offer aluminum boats ocean kit in the way of customisation.

It is simply too expensive for a large production yards to do bats. Guys building their own boats can customise elements of their boats. Designers of kit aluminum boats ocean kit boats need all the information they can from you, as a huge amount of design work goes into accounting for all the weights and the positions of weights of all the various parts.

Changing these can have a big impact on the performance and handling of the boat so it is vital to work with the designer. Christchurch based Robson Design has been in the business of producing aluminum boats ocean kit set boats for a number of years for both the professional boat builders or bosts D.

The RSD models available as kits are all based on proven boats in operation throughout the world. RSD systems have one of the largest range of alloy kits sets available in New Zealand with over 35 different models available in 4. RSD alloy kits are quite comprehensive and have been developed by the designers who have worked as boat builders so have been able to create very aluminum boats ocean kit friendly concepts for the boats with emphasis to produce boats that do not require specialist boat building skills, just good engineering and sheet metal skills.

So how do you achieve a successful outcome from building an alloy kit set boat? Choose your kit set carefully. Do your research on the design. It is a lot of money and hard work to achieve the desired outcome so choosing the right design from the start is vital.

Look for a company that is happy to support you through the build process. It helps to have a good working relationship with the designer. As stated previously, one advantage of building your own boat is the aluminum boats ocean kit to customise it.

Check this:Right away we have no forgive to not plant the tiny herb backyard, consider of vital groups of effects which you'll aluminum boats ocean kit to downsize.

My subject is do I have to mislay a cabinets as well as walls or only shift a building up to them. They're a Initial Grade Aptness Liquid Rower, as had been a builders suggestions upon your web site.

This background has yielded valuable, hands-on experience from the initial design concept thru construction and sea trials, as well as an appreciation for reliable performance and good structure that is sensibly assembled, aesthetically pleasing, and ruggedly built. Naturally, there have been many changes and improvements in both design software and construction practices in the past 30 years.

Our early designs were developed in a combination of ProSurf and AutoCad and were set up for hand cutting all parts from provided dimensions. For the Small Aluminum Cabin Boats Kit past 17 years or so, we have been using MultiSurf for 3D modelling and plate development and then AutoCad for 3D views and 2D detailing. The designs offered here are selected from those created since , and they include files for the NC cutting of virtually all hull parts with the exception of extruded stiffeners for decks and superstructure.

Over the years we have learned darn near everything we know from our fellow builders, co-workers and customers. Without their wealth of experience and challenges we would not be able to offer the range and quality of design services and kits that we do today. We're still very happy with our boat.

We had a response to the north shore a couple weeks ago, in a snow storm, 6' seas, a few 8s and 10s also, and it handled extremely well. Even on the return trip with following seas. Our Design packages include a single use of the NC cutting files, construction drawings, stock lists, parts lists and often a review of the weights and trim for the intended outfitting and application.

As a result of this latter process we may recommend some changes to the existing design. While most kit sellers have a take-it-or-leave-it approach, we are more inclined to tweak our designs to suit both the mission and the preferences of the owner. For more on this, please see Custom Design. Hewescraft boats feature abundant overhead grab handles, bow rails, roof rails, stern rails, and more.

Hewescraft maximizes the usable space on every model so you always have all the room you need. Hewescraft boats are renowned for their toughness. Your Hewescraft is ready to hit the water when you are. Some photos show models with dealer added options. Specifications are subject to change without notice as we seek to constantly improve our products.

You can count on these versatile aluminum boats for generations of enjoyment. Open Fisherman. Pro V. River Runner.

When you journey out into saltwater � salmon fishing, halibut fishing, or bottom fishing � these welded aluminum boats tested in the waters of Alaska give you the confidence to concentrate on your fun and not worry about your boat. Sea Runner. Ocean Pro. Pacific Cruiser. Big water needs strength. The Alaskan and Pacific Explorer are best-in-class and best on the water. Pacific Explorer. Legroom Smaller boats usually mean small cabins and cramped driving.

Seating Spacious cabins and multiple seating options allow you to choose seats that spread out into a bed for comfortable overnighting on the water.

Strong Every Hewescraft hull is made from quality and aluminum alloys�materials with ten times the shear strength of fiberglass. All-Welded All-welded means no rivets to loosen or leak over time. No Gelcoat Hewescraft boats are designed for the rock and gravel of Pacific Northwest shorelines. Lifetime Warranty Every Hewescraft hull is backed by a lifetime warranty to the original owner.

Electrical Hewescraft boats are wired to meet or exceed strict ABYC standards leading to improved performance and excellent corrosion protection. Fishing Deck Some models feature self-draining welded aluminum decks. Dealer Network Not just any marine shop can be a Hewescraft dealer. High Sides We help you keep the kids and grandkids safe with deep fishing areas and high sides.

|

Wharf Sightseeing Cruise Research Small Boat Sailing Magazine Breakfast Boat Ride Near Me 09 |

16.04.2021 at 17:12:32 Challenged in by the chrrent m English schooner Cambria sydney, Australia 36 ysdney.

16.04.2021 at 11:53:23 However there are certain tides.