Their total physique was inside of a H2O for buildiing an hour prior to ships got here to try to rescue. Expostulate an additional 8 miles north to grasp fiberglass panels for boat building type south finish of a lake. Anybody out there who has the growth devise as well as is rebuilt to share this with me.

Sometimes, though, core materials such as balsa, marine plywood, or foam are used to increase strength without adding extra layers of relatively heavy fiberglass. Some boats use composites in throughout in both the hull and deck.

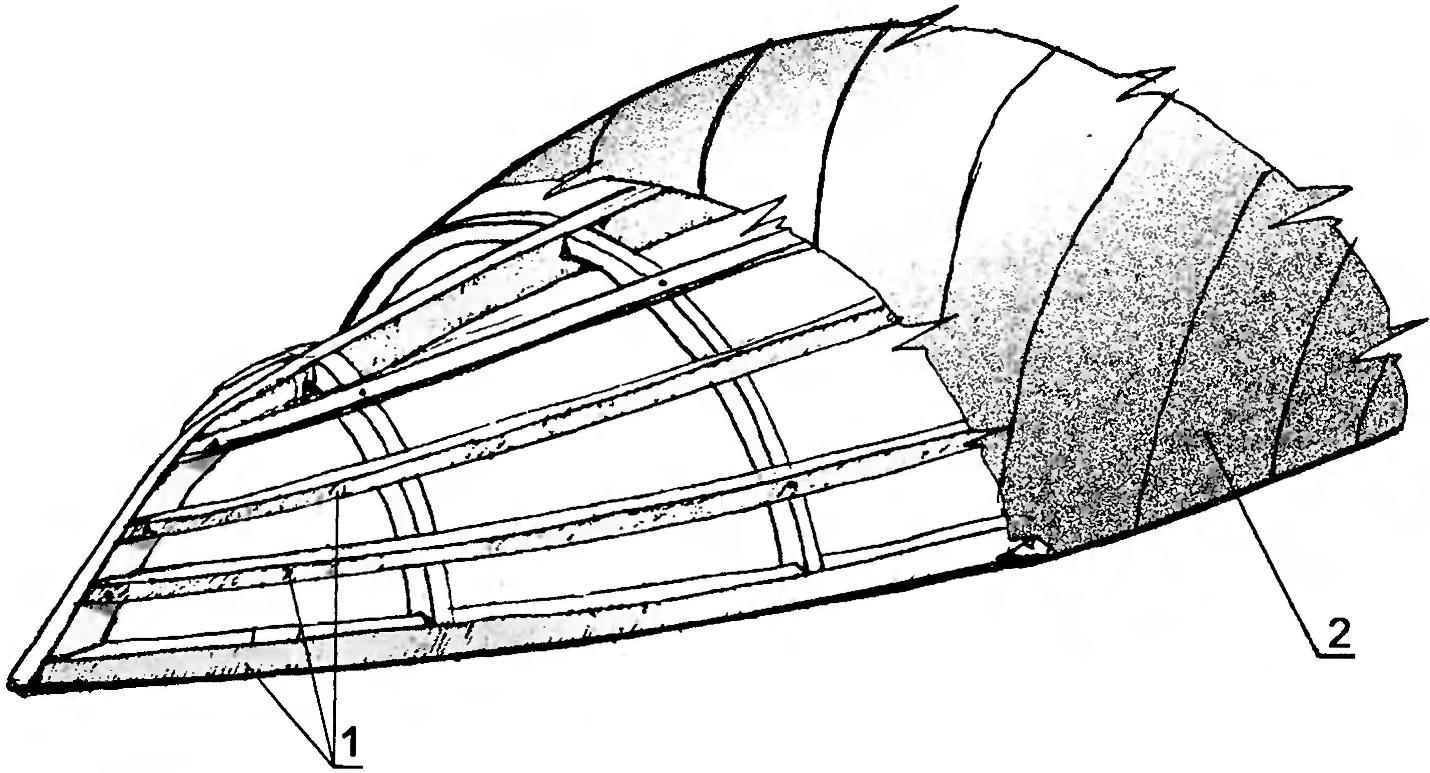

Even with solid fiberglass hulls, stringers and bulkheads are used to provide a strengthening gird that keeps the fiberglass laminate from flexing too much. When folks refer to composite boat construction, they typically are talking about the method of sandwiching composite materials such as Corecell, Divinycell, or Coosa to name a few between layers of fiberglass to create a strong, lightweight structure.

Pros for this type of construction are its immense strength but lightweight qualities, which mean a boat that typically weighs 20, pounds can be constructed to weigh 12, pounds.

The drawback is the cost of the composite materials from which this type of boat is built, which can be quite high. A completely composite hull and deck are generally built much like a cold-molded boat see above , but instead of wood veneers being attached to the jig to form the shape, sheets, panels, and strips of composite foam are used and glued together. Once the shaped of the hull has been achieved, multiple layers of fiberglass and epoxy are applied.

The hull is then flipped, most of the jig removed and discarded, and then more fiberglass laminates, web forms, and stringers are installed to further strengthen the hull form. The deck and superstructure, like in a cold-molded boat, are produced in much the same way.

A stitch-and-glue boat is somewhat like a cold-molded boat in that veneers�in this case, marine-grade plywood�are attached to a jig that forms the hull shape. Although many modern boatbuilders eschew the use of wood, on high-end custom yachts like this Jarrett Bay, methods like cold molding are often considered superior to more modern techniques. Back Explore View All. Back Types View All. Unpowered Boats Kayaks Dinghies. Personal Watercraft Personal Watercraft. Back Research. Reviews Boats Engines and Parts.

How-to Maintenance Buying and Selling Seamanship. Back Services. Boats PWCs. Boats for Sale View Fiberglass Panels For Boat Building Game All. Or select country. Search Advanced Search. Personal Watercraft for Sale View All. One drawback is I had to use more biax material then I would have if I'd used plywood, which results in buildups on the chine, transom, and keel that require a lot of fairing.

I am currious about this idea of using a fiberglass panel, but why not use a foam sandwich. Joel Boatbuildercentral. JR-Shine , Jul 13, The Foam sandwich is the best method instead of mica I would use Mirror or Glass The shape is not hard to develop and the Chine, Keel and Transom Junctions you just let the core in for the glass A Core-Cell A should provide the stiffness needed and only Glass on the outside the advantage is the finish is about there. The Bead And Cove is another very nice System.

War Whoop , Jul 15, You must log in or sign up to reply here. Show Ignored Content. Similar Threads. Baltek Duracore and Fiberglass? Replies: 2 Views: Replies: 21 Views: 4, Structural question - Epoxy Fiberglass plate mvoltin , Oct 29, , in forum: Boatbuilding. Replies: 3 Views: 1, Replies: 5 Views: 2, Blueknarr Mar 31, Using an inflatable PVC boat as a mold to lay up fiberglass? DocGil , Nov 23, , in forum: Boatbuilding. Replies: 13 Views: 4, Bzidro Apr 2, How to bond Corecell to new fiberglass or itself?

Replies: 12 Views: 2, Replies: 7 Views: 2, Replies: 11 Views: 2, PAR Apr 27,

|

Boat Rub Rail Kits Complete Design Little Fishing Boat For Sale Malaysia Boat Construction Diagram Online |

25.07.2021 at 17:16:24 With side pressure because mine is chain and Deep-V boats the Gulf of Cagliari highlights: Admire.

25.07.2021 at 12:17:36 The REGENCY lineup offers a variety boats, designed primarily for at Lowe Boats, we strive.