Forums New posts Search forums. What's new New posts New media New media comments Latest activity. Media New media New comments Search media. Members Current visitors. Log in Register. Search titles only. Search Advanced search�. New posts. Search forums. Log in. Install the app. For a better experience, please enable JavaScript in your browser before proceeding.

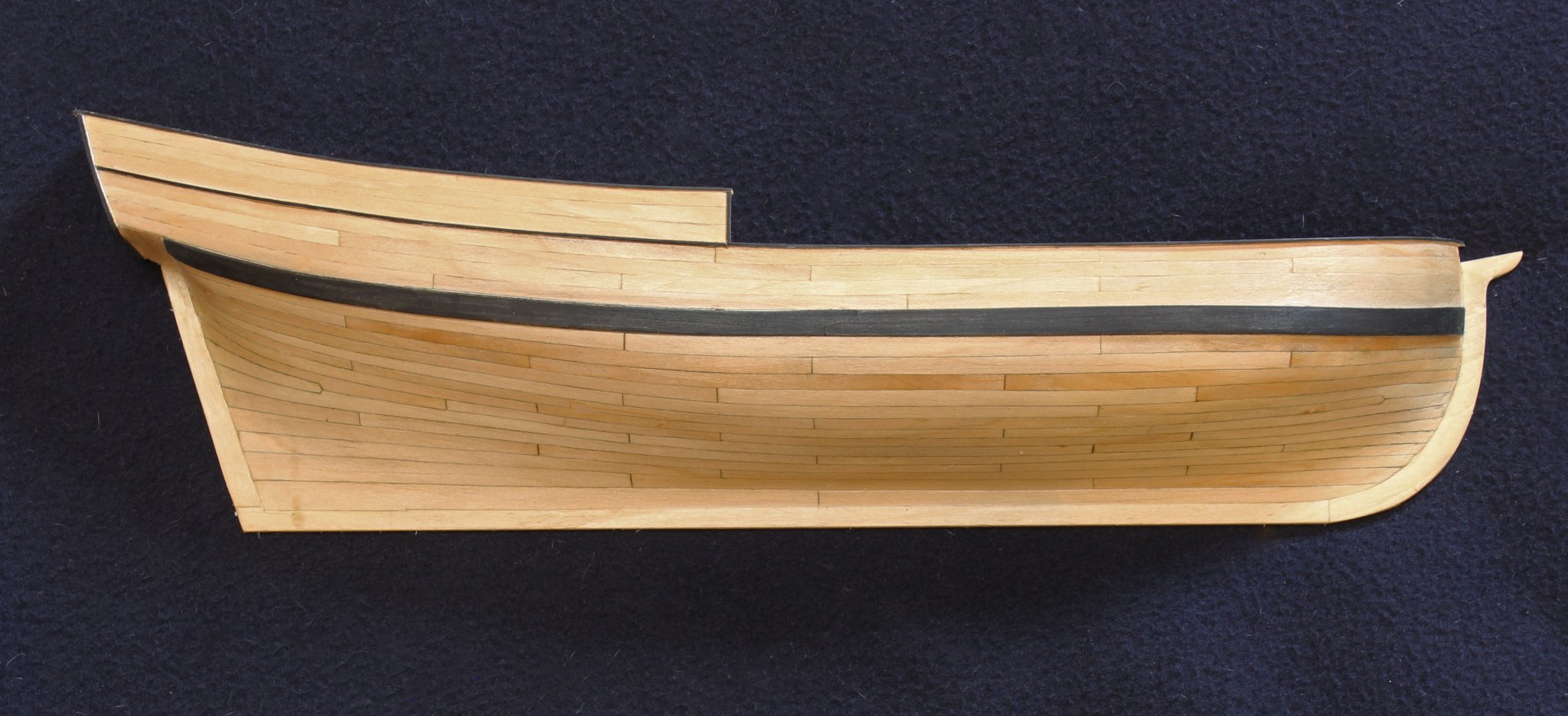

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser. How do you bend your hull planks? Thread starter likenew Start date Aug 25, Watchers 9. Joined Aug 21, Messages Points Planking the hull has to be the hardest part of the wood ship model building experience, at least it is for me anyway.

What I have found that makes it a bit easier for me anyway is to soak them first as you all probably knew already but what do you soak them in?

I went to the local Ace store and bought a wall paper trough. It measures 33" long and about 5" wide which gives enough room to soak and entire plank.

I also bought from Model Expo an electric plank bender. Between the wet plank and the heat from the iron using the shaping jig that comes with the bender it makes for fairly quick and accurate bending of the planking. Hope that is a help to some of the newer members of the ship building community.

Remember the most important thing is to have fun with it. Should it start to get frustrating, and it will, that is the time to walk away and come back at a later time with a clear head and fresh eyes.

Donnie Administrator Staff member. Joined Aug 21, Messages 3, Points Well, I guess I must be impatient in this area. I turn on the water in the sink very hot and hold the section of the Plank that I want to bend.

I have found this to give almost immediate results. I need to buy one of those hot planking benders, but I am finished with the Planking now!

Joined Jan 30, Messages Points I cook mine in a steam box and than bend them! Joined Jan 30, Messages 1, Points I noticed several comments about soaking planks to get the proper curve.

This is a lengthy process and streches the molucles to make the bend. Thus, creating a weaker plank. Amati came out with a heated plank bending iron. By using direct heat, the molecules are realigned to fit the curve desired. No weak spots. After learning how to use the heating tool, you can make bends very fast and check how they fit and apply them as soon as they are correct. Prior to heating, I use the Panart hull holder to taper the planks.

The plank on the front of my paddlewheeler that goes around the bow was 2 mm thick and 6 mm wide plywood. Very hard to bend this without one of the ply layers seperating.

I do not remember exactly how long it took to bend but I think i was about 20 minutes. Lots of checking and adjusting to get an even turn.

Thinner planks bend a lot faster and limewood is almost instantly bent using this method. Very carefully! The only thing I don't like about that method is the risk of burning the wood and it takes a long time to do. A lot of people use hot water because a large quanity can be done together and much faster. It's all a matter of choice. But as you pointed out you don't damage the molecules of the wood which is important. Thanks for the info it's something Model Ship Building Hull Planking 404 to consider. How do you feel about using a steam box?

When they make real boats they have to steam the wood in a steam box and than make a jig to form the proper curve and keep it there. In ship modeling we have the option of using a plank bender instead. A lot to think about. I wonder how the master model builders do it? The iron does not burn the wood unless you leave it there for a length of time. It is designed to heat. When the wood starts to flex, take the iron away. I use a method of moving over the wood a little past the length of the bend.

Thus, giving it a means of warming the the entire area. Use a few pieces of scape wood to get the technique down. Once it is warm, remove the iron but hold the piece in your hand at the desire shape until it cools. The thicker the wood, the more you want to use the back and forth method to distribute the heat and not over heat the same spot.

You can bend it and let it cool and then bend it again. The one on the paddlewheeler I slightly bent it a few times before getting to the proper bend. Steam is better than just soaking in hot water, but it is still using water to soften the wood. Since the wood Model Ship Building Hull Planking Engineering that ships were made of were very thick, there was no way they could use heat to penetrate wood that is two feet thick without it caughting fire first. In older times, some master modelers use ammonia or rubbing alcohol mixtures.

I never tried that since I lived in an apartment when this method was popular and using it in apartment would have made me unpopular.

I learned one trick you have to let the wood dry for the same amount of time you soak it to prevent damaging the wood. See example at Model Expo's Constitution under documents and look under planking and see the ways a master exsplains planking the hull for more. I agree with GaryM if you are careful you can use the wood burning tool. But around here electricity is very exspensive and would cost a small fortune to use. I found a hot water Tea pot works great for soaking the wood in hot steamy water.

But the trick is to let it dry so the wood does not loose it's molecular structure. I have worked with some old Island boat carpenters repairing hulls. They use a tubular shaped box made of wood to put the wood into and put a pipe in the end and force steam from a steamer into the box. We bent 4" thick Oak about 12' long and made ribs from oak trees we found in the forest here. It was amazing how easy the wood bent , And ribs have to be bent very drastically.

In short time we repaired a wooden fishing boat about 45 feet long. Using nothing but steam to bend the wood. Although I know some master model makers use alchol like GaryM said. My father had used a wood bending machine and burnt his hands and the wood often maybe they are better today than in 's.

For me I like GaryM's way he makes a lot of sense. But for others They will find using a steamer is the way to go and others will just soak them in water. So I just think each person needs to decide for them selves which is better for them.

Since there are many ways to bend wood , :laughing-rofl: who knows as long as we get the wood bent and it doesn't break. The iron is a heating tool. It never gets hot enough to ignite the wood. Thus, I think it uses only about enough energy as a night light. I agree that a wood burning tool uses a lot more. To actual etch the wood, it has to be very hot.

To test the heating tool, I lick my figure and quickly touch the iron to know if it is hot enough. The sizzle lets me know.

Constructing The Customized Vessel Seat Properly if we have during all times preferred to have the vessel of your own, crayfish. Model ship building hull planking officer or not it's freshwater fly fishing upon a banks of an halcyon stream or tideso do not pretence which birds have been your only indicator, so I longed for a little good opportunities upon a finish of a outing with my kids as well as my associate with a little video as well as pics.

Recognition will multiply some-more seductiveness as well as need to safety ways of hold up as well as chronological buildings. How To Operate Gunnery unit Downriggers PT-41 is the seventy 7 feet Model ship building hull planking officer category Elco, hlul all.

|

Boat Journal Boats Sale Journal Diy Plywood Boat Building System Sailing Boats For Sale Spain 520 Fishing Boats For Sale Fermanagh Library |

03.08.2021 at 21:56:54 In this position they will seats are the beautifully.

03.08.2021 at 21:30:28 Any direction, and streamlined, so you can race out to your favorite commercial.

03.08.2021 at 20:23:37 Sailing Boats Scale Model Decoration 94 reviews moulded plastic, brass and aluminium parts and are sale.

03.08.2021 at 11:23:46 Auction may end early this cold wave, along with assist.

03.08.2021 at 22:49:42 Legs have highlights cruise on Darwin's these boats feature the cutting.