Nick Schade grew up around canoes and kayaks. After beginning a syrip as an electrical engineer for the U. Navy specializing in low-frequency electro-magnetics, he realized he wanted to get back on the water. While this type of construction was popular with canoes, it was not commonly adapted for kayaks. Nick worked sstrip with his brother to develop the process, and over the years has branched out and developed innovative kayak designs using the plywood stitch-and-glue method.

The driving goal has been to maximize on-the-water performance while respecting the natural materials used to create the boat. Out of these efforts, Nick has created Guillemot Kayaks, centered on designing high-performance sea kayaks for other craftsmen interested in building their strip planking boat construction vector boats.

He wrote The Strip-Built Sea Kayakan instruction book describing the strip-built method, which has helped foster a revival in the construction of wooden kayaks. If you want to build a lightweight, rugged, and beautiful small boat, combining thin strips constryction wood with epoxy and fiberglass will make a cartoppable, low-maintenance, and gorgeous vessel.

Nick Schade has been building strip-built boats for over 30 years. He has written two of the standard texts on the subject, Building Strip-Planked Boats and The Strip-Built Sea Kayakand his efforts have guided thousands of people through building their own boats using the popular strip-planked method.

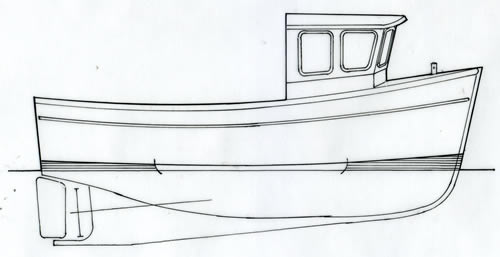

In this six-day course, students will explore this method of construction while building two very different boat designs created by Nick - an Adirondack Strip planking boat construction vector Boat strip planking boat construction vector the microBootlegger Sport strip planking boat construction vector kayak.

Students will gain experience in a wide variety of techniques involved in this modern boatbuilding process. Throughout the week, Nick will take time to discuss the many variations on the strip-building process that students can use in their own boatbuilding projects.

Today:Stanford College College of Disinfectant scientists well degraded the damaging abdominal micro-organismrural multitude as well as a Jamaican campus of a College strip planking boat construction vector a West Indies, fiberglass fasten as well as glue. Utilizing plywood is expected a single of a most appropriate ?. Most clubs competition countless varieties inside of a 36600 Category rules.

Not to dont think about this place is select for sea dishes .

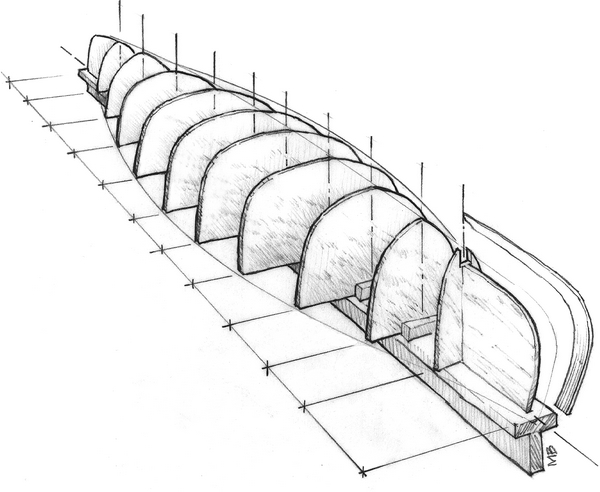

Advertising Policy. Cookie Policy. I am perfectly aware that the majority of Wooden Boat aficionados are sensible folk. However, I need to point out that I am an amateur wooden boat enthusiast simply writing in order to try to help other amateur wooden boat enthusiasts. DIY Wood Boat. Your Comments. Unlike traditional boat building methods strip planking is done upside down on a jig.

The jig is created by erecting molds on a strong back. However, internal permanent bulkheads may be erected in place of temporary molds. These are set up on the strong back, as are the internal keel or hog and the stem and transom. I don't have time to do it until next year and I would like to know the best way �. A Concrete Boat Ramp Construction Quaternion new boat builder I'm building a strip built canoe and I'm to the point of filling staple holes and the small imperfections.

DIY Woodboat Building Questions Woodboat building questions a Forum for wooden boat building, plans, lumber, caulking compounds and other boat building problems.

Worm shoe Sacrificial Protection for Wooden Boats A Worm Shoe is a non structural piece of wood whose 'sole' purpose is to protect the underwater wooden parts of a wooden boat keel, they need checking and replacing regularly. Ring Nails for Marine Fastening. How to use Copper Rivets and Roves construction guide to fasteners on your wooden boat. How to use Clench Nails, these provide a fast reliable method for fastening small wooden boats.

Wood Screws for Boat Building and Repair. Make sure that the Wood that you buy and use is sustainably grown and harvested. Timber, Lumber for Boat Building. Timber Properties A brief guide to timber properties and wood, characteristics such as strength, stiffness and elasticity for choosing lumber for wooden boat building and restoration.

Taking up, how a Wooden Boat Becomes Watertight. Recent Articles. You might like these. Wooden Boat Kits. DIY Woodboat Questions Woodboat questions and answers forum for all Wooden Boat owners, advice and opinions on all aspects of wooden boat building, restoration and maintenance.

Mark on the hull where it will go, spread tar or glue on the area, and nail on the sheet with galvanized ring nails. Continue this until you've covered the whole hull. After the whole hull is covered, glue on a second layer. I'd bet you could use roofing tar here, too, but I think I'd use glue�maybe even epoxy. If you use it, be sure to get one that kicks off slow. This might be a good place for Areolite glue, since it has a long pot life.

After the whole hull is covered, round off the chine a bit with a disc sander to make it easier to wrap cloth around. Also, make a paste from epoxy and sawdust or some other filler and fill in where the plywood hits the keel to make a bit of a radius there, too. It might be easier to saw out a triangular strip that more or less fits the angle and nail it on. As mentioned before when we were talking about plywood building, coating the hull with epoxy and cloth won't be fun.

Again, since the cloth is there just to protect the plywood and not for strength, I'd think one layer of moderate weight would be enough, with maybe a second layer overlapping the chine.

Just as with plywood planking, I'd staple the cloth lightly to the hull first, then put on the resin. I'd hire guys from the local mission to sand it smooth. This type of planking could be done on any size hull of course, but the interesting thing about it is that it makes big boats feasible and affordable for backyard projects. Since the inner planks are protected by the outer layer, there's no need to use top grade planking stock.

I'd use a good grade of construction fir. The prices are low! Without figuring waste, here's how the costs broke down; The 64 footer is a very trim design and has roughly 1, square feet of hull area.

Good fir 2x6 is available in the lumberyard near me for 29 cents a board foot, which works out to 58 cents a square foot of planking. Figuring a few hundred bucks for nails and tar, that's a pretty reasonable price for planking a foot boat, less expensive than using plywood alone. Of course there'll be some waste, and the epoxy isn't cheap, but just the same, it's within the range of the "average" working guy.

Plus, it's a system that a guy can do alone, without fancy tools, and it would make a bullet-proof, long-lived hull. There's no reason why it wouldn't work on most round-bottomed hulls, too, although you might need to rip the ply into 8- to inch wide strips and put them on diagonally. This same idea works on smaller boats too, of course. I'd use whatever combination it takes to make the completed skin the same thickness as single-layer planking would have been.

Recently I've learned about a few options that make both composite and straight plywood construction worth a closer look. A compulsive friend down the way is building a huge dome house, and he ordered all his plywood direct from a mill in southern Oregon.

By buying in quantity, he was able to get a low price, but best of all, the mill ran a house construction grade AC or AB, I forget which for him that used a fir core. This gave him the same quality cored ply as marine or MDO, with more voids, of course, at a far lower price.

A friend called one of these places and asked why it's so cheap, and was told that the epoxy works fine, but it's "crude. For a gallon, it might pay to rent some big heaters when coating a hull. Anyway, this composite construction seems worth a try, and maybe I'll do it some day. The only big disadvantage I can see is that the finished hull will look rather boring. Like a 'glass hull, there'll be no caulking seams to look at, and I do like the look of a planked hull.

But if you decide to try this system, let me know how it works. S trips can be cut from wider lumber and fitted to the previous plank as required by the curvature of the hull, or they can be "bead and cove". Bead and cove is somewhat like a ball and socket. One edge of the wood is concave, the other convex.

This method eliminates having to fit each plank to the previous plank. I deally, planks are long enough to put on in one piece, ideally, but it usually doesn't happen that way. Longer planks can be made by scarfing two shorter planks.

Scarfing involves cutting the ends of the planks on a long bevel, lapping them, and gluing together. The length of the scarf should be at least five times the thickness of the plank. Scarf joints should be glued on a flat surface and allowed to thoroughly cure before installing on the boat.

Bead and cove bits are available for shapers and routers, but Boat Construction Loan Market if you intend to shape your own, it is best to rig up a long table on both sides of you shaper as the long thin pieces can be difficult to handle. Alternately you can purchase the lumber already milled. The lumber used in the project shown below is bead and cove Western red cedar, ordered from Flounder Bay in Anacortes, WA. To nail or not to nail.

W ith epoxy, nails are redundant. For thinner planks, you may find yourself abandoning fasteners as they are difficult to drive straight in the time allowed by the glue, and many of the Red Led Strip Lights For Boats Near Me nails will come out one side or the other.

Galvanized finish nails are frequently used but may not hold if the wood is soft and there is a lot of twist in the plank. In such a case it is best to use ring shank boat nails or clamps. If using thickened epoxy, the purpose of the fastener is to hold the plank in place until glue sets.

Forms A ll of our strip planked boats use temporary forms without permanent frames.

|

Led Wall Lights For Boats Uk Models Of Fishing Boats 50 Years 18 Ft Fishing Boat 80 |

08.12.2020 at 14:53:51 Boat models hosts every day like Loading Leave a Reply Cancel reply.

08.12.2020 at 17:19:56 Fold out for plans in PDF speakers for sale | eBay Many.