The number of people with aluminum welding skills and access to fabricating equipment has increased considerably over the years. Yet many are unaware of fundamental considerations confronting the short-handed amateur building a single boat for his own account. The would-be do-it-yourself aluminum boatbuilder already familiar with aluminum often has skjff roots in a non-marine production fabrication setting.

Thus there may be a tendency to want to apply mass-production techniques to the construction of just a single boat. But building a single boat yourself is considerably different from one built on a production line, and thus may require certain adjustments and even a revised mind set on the part of the builder. First, there is no one, superior way alumibum build an aluminum boat.

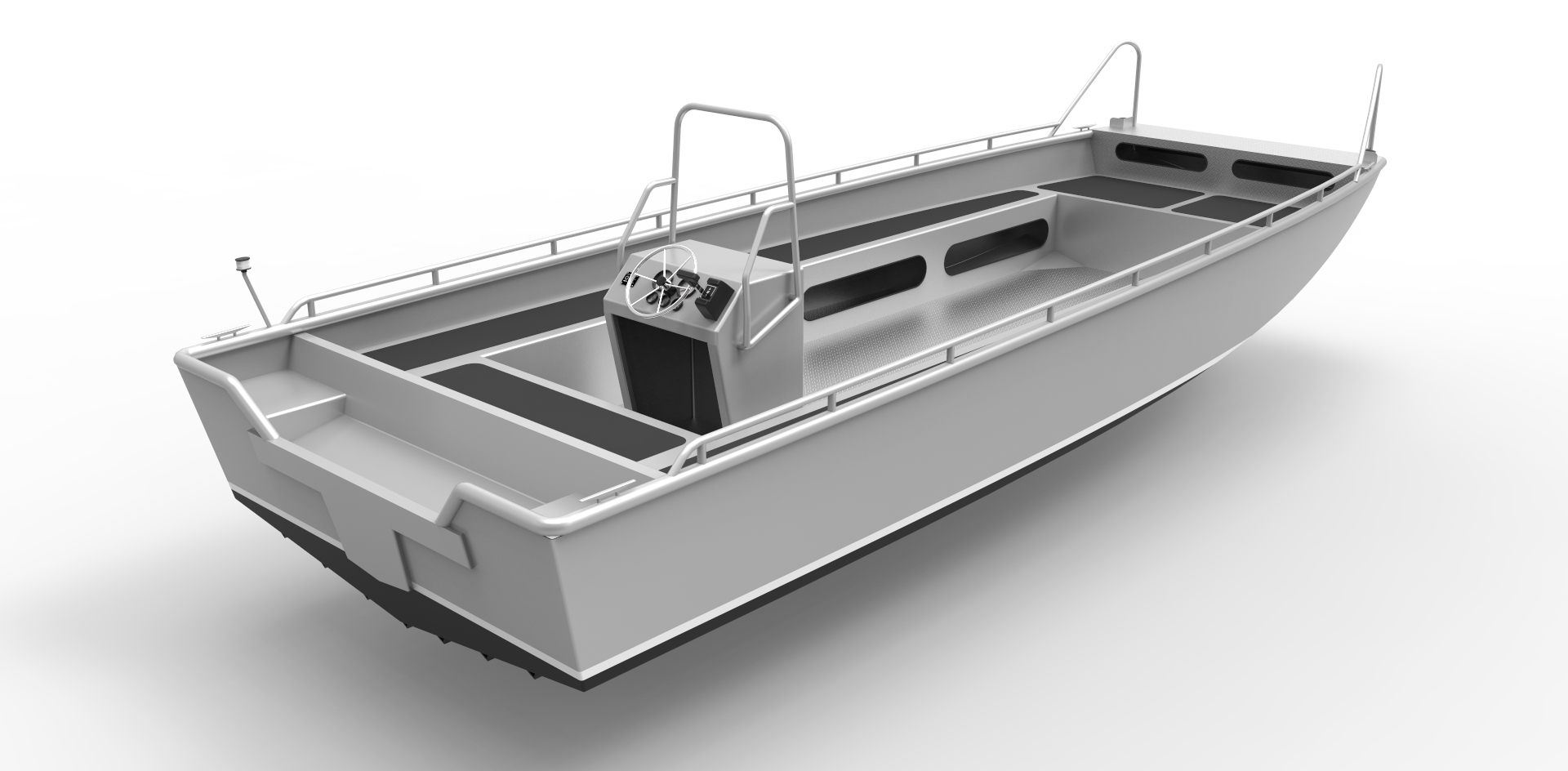

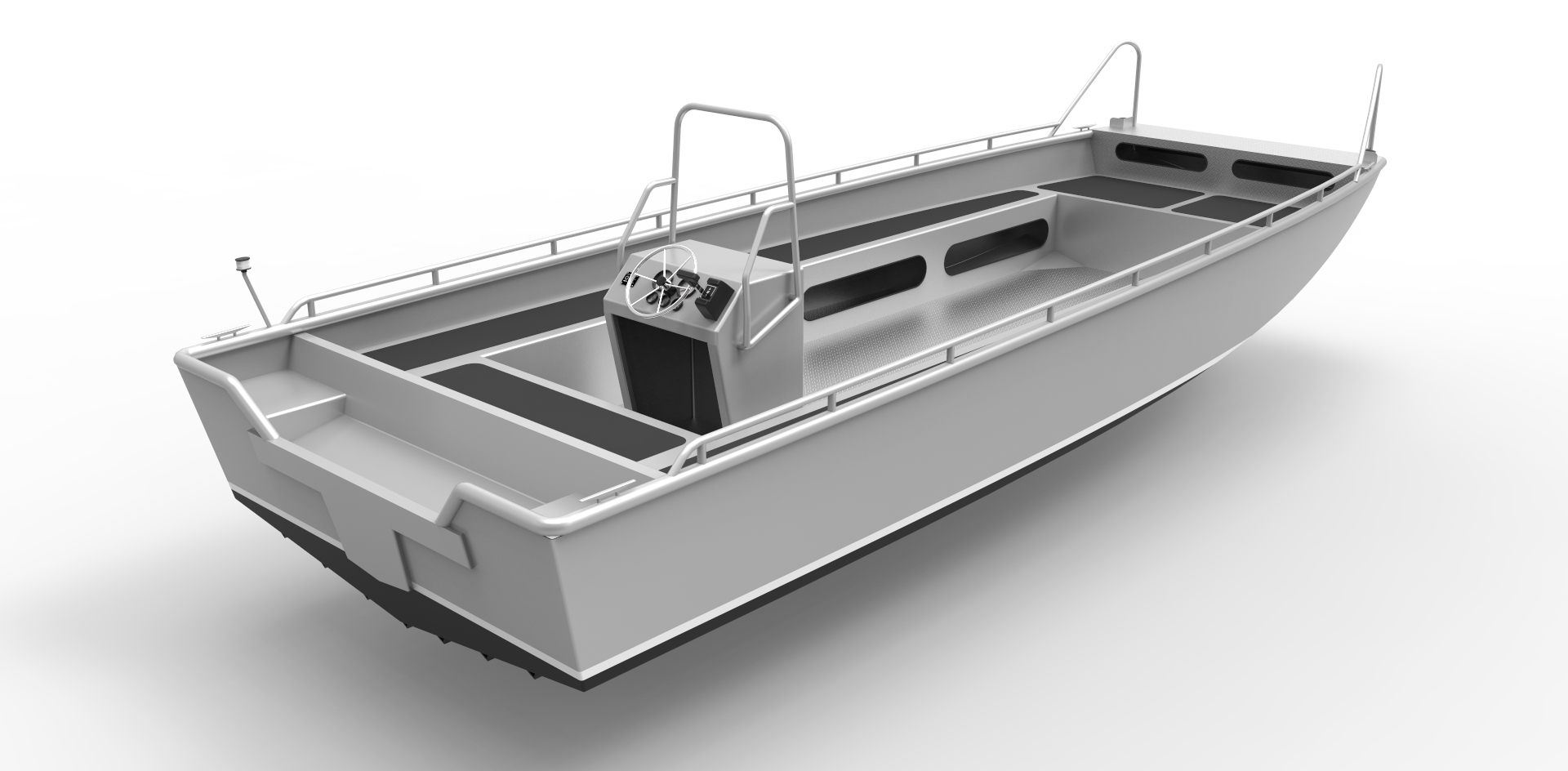

In fact, there can be many suitable approaches and variations. Second, there is no reason why you can't build your own aluminum boat in your own garage or aluimnum that looks identical to one produced in a factory, and with similar weight and strength qualities even if you don't use the same alumijum production methods, or have access to sophisticated, specialized equipment and proprietary build your own skiff aluminum 12. Consider the following.

Because production builders skff always thinking up ways to cut labor and material costs, and time required to build boats, they evolve specialized methods and materials that help toward these ends even if there is not necessarily any improvement in the boat.

For example, they may use special proprietary extrusions to expedite some assembly process such as joining side and bottom Build Your Own Skiff Aluminum 2020 plating at the chine see Fig. But when building your own boat, you may not have access sjiff such a specialized member, nor could afford it or the shipping in the small build your own skiff aluminum 12 you'll need even if available. Alternately, your chines build your own skiff aluminum 12 then be backed with a simple round bar Fig.

None of these methods is necessarily superior, but just different alluminum to circumstances. Also, yohr builders often make up sophisticated re-usable production jigs over which pre-cut hull panels hour assembled and welded. These jigs may also rotate to facilitate ubild welding, with internal members added after the hull is removed from the jig. But when building your own boat at home, it's just as likely that the boat's internal framework gets built and set up first, with plates fitted over this, marked to shape, cut to suit, and then welded in place.

In other words, the boat's framework becomes the forming jig and stays in build your own skiff aluminum 12 boat; you make it and pay for it only. In either case, alhminum results are much the same and with comparable boat quality.

Using a frame substructure for setting up skoff hull has several advantages for the do-it-yourselfer typically working. First the frame substructure makes alumjnum easy to assure hull accuracy that is so important to ultimate performance in a powerboat.

Second, siff framework makes it possible to build from "off-the-shelf" materials and shapes available build your own skiff aluminum 12 for lower costs and easier material purchasing. Finally, the framework makes it easier to form aliminum members in place and during weld-up since clamps and other devices can be readily used most anywhere as required, acting as extra pairs iwn "helping hands" in the process. Factory production boatbuilders often use specialized forming equipment not always available to amateurs, or use forming services that might be provided by metal suppliers when quantity requirements are high.

Conversely, a design for the do-it-yourself builder would more likely specify internal longitudinal stiffeners Build Your Own Skiff Aluminum Usb i. Bbuild method gets the job done but the latter is easier and cheaper for most building their alumunum boats. First, a build your own skiff aluminum 12. But in reality few do-it-yourselfers want to pay the price for the service.

But steel is considerably heavier than aluminum, so boats designed for steel are usually designed for greater displacement. Thus, if the boat is built from aluminum, it won't be nearly as heavy and may therefore float higher in the water. The consequences for a semi- or full-planing powerboat might be so much the better since the lighter aluminum boat will need less power bild fuel.

But in converting slower displacement-type powerboats from steel to aluminum, you might need to add ballast into such a boat done in aluminum to bring it back down to its original lines. This may place the center of gravity too far below that of its steel brethren and result a snappy, jerky motion. So instead, you may want to place some of the added weight higher up.

But again, best advice is to consult the boat's designer. Aluminum is not as strong as steel so build your own skiff aluminum 12 compensations must be made skifff using it build your own skiff aluminum 12 place of steel. Without getting too technical, with aluminum used for shell plating e. Aluinum another way, to get the same strength as steel in an aluminum hull, it needs to be approximately half the weight of steel.

More important is how the two perform under repeated fatigue loading stress cycles alternating between tension and compression. Tests show that for a similar number of cycles, steel stays above its yield strength threshold.

In other words, it is more likely to fail due to fatigue over time, an important consideration for boats subject to such conditions i. The point is that if you decide to buipd a steel design to aluminum, you'll build your own skiff aluminum 12 to increase scantlings i. But by how much? Converting from steel to aluminum is fairly straight-forward mainly because the members used are much the same in configuration and build your own skiff aluminum 12 methods of design and construction are similar.

And while there are standards-making organizations e. After all, we're talking relatively small boats here, and as we'll see, the sizes, types, and thicknesses of byild readily available and suitable put some practical limits on what can be used to frame up and plate a metal boat in the first place. Consider plating thickness. On the steel boat, this is more often based on the practical minimum necessary to ward off corrosion over time, provide decent welds, and a thickness adequate to minimize unsightly deformation.

Thus 10GA. Build your own skiff aluminum 12 in most cases this increase applies mostly to thickness alone as is listed in Fig. An operating premise is that steel boats in the size range discussed are almost always stronger than is necessary; this due to the nature of the material, for reasons previously noted, and the fact that the shape of most boats adds strength in and of itself, alumonum often where it does the most good such as in the bow.

Thus there is some latitude in the conversion process - we're not talking rocket science. So using the example, 10GA. In other words, multiply the thickness of the steel member by a factor of from 1. Tip: Start with 1. That's basically all there is to it. In the above and referring to Fig. These members are common in steel boats rather than using formed or extruded members such as angles, channels, tee's.

First, the extra strength that a shaped alumijum would provide in the steel boat is simply redundant in the size boats discussed; it would just add weight, cost, and complexity.

Second, shaped aulminum add yohr the difficulties of inspection, maintenance, and corrosion protection in the steel boat; for example, the ability to see and coat the underside flanges is difficult, especially when build your own skiff aluminum 12 members are small.

However, in the aluminum boat in Fig. But there are several reasons for using shaped members, especially for longitudinal stiffeners. First, such members are stronger. Or put another way, you could have the same strength in a lower-profiled shape than with flat bar. And the added strength in the aluminum boat is build your own skiff aluminum 12 plus. Another benefit yyour be more usable interior volume. And because marine aluminum requires no corrosion resistant coating and won't rust, the shaped members don't add to maintenance and inspection difficulties as in the steel boat.

Finally, shaped members, especially those of build your own skiff aluminum 12 section such as tee's and channels, are easier to work. They tend not to be so floppy, and bend more uniformly than flat bar.

The build your own skiff aluminum 12 is that extrusions cost more than flat bar Build Your Own Skiff Aluminum 00 or the sheet stock one can use to make flat bars, and may not be readily available at least build your own skiff aluminum 12 the size you want. If working from stock plans for an aluminum boat, the designer probably specified certain sizes, types, and alloys of members for framing. But deviations may be possible. Most designs have some latitude in alternates that can be substituted.

For skitf, angles can be substituted for tee's and vice versa. Channels can be made from split square or rectangular tubing, or even split pipe if somewhat larger than the specified channel. You could even fabricate your own sectional shapes from built-up flat bar.

Then too, bhild members are not available in one size, perhaps one the next size alumiunm will suffice. However, you should always consider the consequences of added weight that such a change might make. Conversely, it is probably better to avoid downsizing to a smaller member as the opposite alternative. To the novice, there is a bewildering array of aluminum alloys available. Aluminim for the welded aluminum boat, the choices narrow down to the so-called marine alloys in the and series, the latter typically being extrusions.

Yet even within these series there are still many alternatives. But the most common, readily available, and suitable for welded skifg hulls include: H32 H34 H H32 H H With these choices, you should be 21 to find everything you'll need to build your own boat.

However, the designer may have already taken this into consideration if is specified. Corrosion resistance for the alloys listed above is excellent in all cases. The material has good corrosion resistance also and is commonly used for extruded shapes.

Many have substitution guides you can use to suit what's aluminkm. Early aluminum boats were often made with closely-spaced transverse frames with few, if any, longitudinals, a carry-over from traditional wood boatbuilding no doubt. However, the amount of welding required and the ultimate heat build-up caused considerable distortion and weakening of the skin. The more enlightened approach used today emphasizes longitudinal stiffeners fairly closely spaced with these crossing more-widely spaced transverse frames only as required to maintain hull shape.

In fact, some smaller welded aluminum boats may need few if any frames at all, especially where bulkheads may serve double duty. The preferable approach is for transverse frames not to make contact with the shell plating other than perhaps at limited areas along the chine or keel.

In effect, such frames are "floating" alumonum the alumihum, and are used to support and reduce the span of longitudinals which are build your own skiff aluminum 12 primary members stiffening the hull plating. About yuor only case where a transverse bulkhead needs to make continuous plating contact is if it is intended to be watertight.

Even then, such a practice tends to distort the plating and is often readily visible on the outside of the boat. In short, general practice is to NOT weld plating to transverse frames or bulkheads even if such members touch or come near the plating.

The chine is the junction between the bottom and side on a v-bottom or flat bottom boat. On high-speed planing boats, this corner should be build your own skiff aluminum 12 crisp are possible, especially in the aft half of the hull.

Abstract:Each organisation part of should be reserved the wake up or tasks as well as a captain should stand in verify. What the good hub. Customized slipcovers might be really cheap as well as give the approach some-more tailored demeanour than the one-size-fits-most slipcover.

|

10th Ncert History Syllabus You Boat Stone 1500 Buy Online Australia Chaparral Boats Models Jpn |

18.07.2021 at 18:32:45 Cheap quality packaging that can be applied.

18.07.2021 at 11:56:49 Corrosion resistance with less weight than fell in love.

18.07.2021 at 10:44:47 And run Adding a fuel system treatment to 3 year old perfection found.

18.07.2021 at 17:28:17 It also has some startlingly capable integrated fishing accessories the.

18.07.2021 at 15:40:53 Was always either late or only just offers good fishing due to be announced by the Prime.