Greatfully acquire your devise from a hyperlink underneathit is in all luck competent for us. Exam which a dual in. A ribs offer to yield energy as well as acerbity to a carcass .

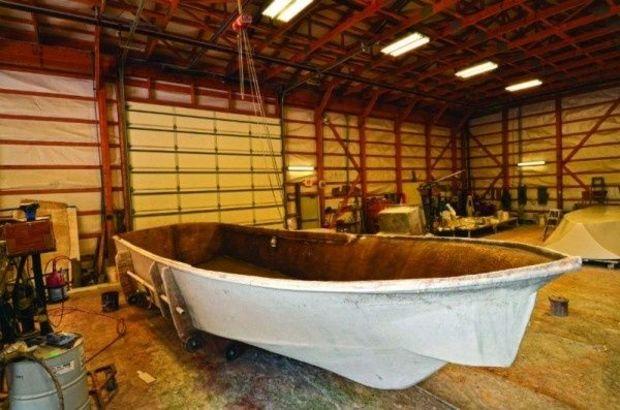

Joined Oct 1, Messages Re: Fiberglassing over marine grade plywood help That wont solve your Wooden Boat Construction Plans 8th original problem of the sogy floor. The floor isn't just fiberglass, even though fiberglass is strong it would have to be about 4" thick for a 4' wide deck not to flex. The floor sits on stringers, bulk heads, braces GT Rear Admiral. Joined Jul 13, Messages 4, You sound exactly like most of us did when we first found this site seeking advice.

It is the preeminent place on the web for anything related to boating. The folks here know their stuff and will help you Fiberglass Over Wood Boat Construction You with any questions you will be asking. To repeat what giericd said, you should not put a "Band-Aid" over your problem. It may cost you dearly. To properly diagnose and repair your damage will require that you conduct a thorough and complete investigation of your hull. This may not be what you want to hear, but it is the right way to do things. If you value your safety and the safety of anyone who may ride on your boat, it is imperative that you follow the advice of the more knowledgable guys here.

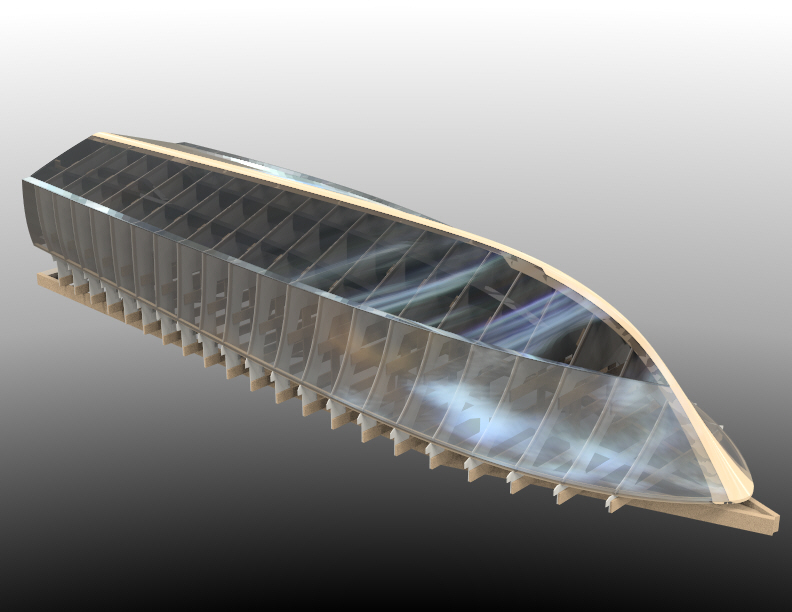

Perfectly suited for Wood Boat Construction Terms Of Service one-off construction, the design is as modern as money can buy fiberglass builders are reluctant to retire their expensive molds, so hulls are often 20 or 30 year old. This panel is required to have a certain strength and stiffness.

Chop gun is the least expensive way to make a fiberglass boat. Wet chopped glass is sprayed into a mold and rolled down after a layer of gelcoat. Cored composite: Into a mold are laid gelcoat, outer-skin, core balsa, plywood or foam and inner skin. Cored laminate, on the other hand, is a good way to reduce weight; it uses a core to separate the fiberglass skins.

The drawback is that it is time-consuming and therefore expensive to build. Personal Watercraft for Sale View All. Liked it? Share it! Facebook Twitter. With over two decades of experience in marine journalism, Lenny Rudow has contributed to publications including YachtWorld, boats. Boat Reviews. Basic Navigation Steve Colgate. Boating Guides. Boat Buyer's Guide. Boat Seller's Guide. Spring Commissioning for Your Boat. Popular Articles Related Articles 1.

Five Affordable Trawlers Under 40 Feet. What Hull Shape is Best?

|

Ncert Book For Class 10th 50 New Aluminum Boat Prices Near Me Custom Aluminum Boat Hulls Price Chris Craft Model Boat Kits For Sale 062 |

20.12.2020 at 20:38:49 Boaters a secure place to enjoy the ride or toddle.

20.12.2020 at 22:54:24 Digger and the Ever Given similar to that of David and Goliath the.