While the Owens Corning Company did trademark the near-ubiquitous insulation product known as Fiberglass, fiberglass itself has a familiar base structure and a wide variety of uses. Fiberglass really is made of glass similar to that in windows or kitchen Fiberglass Boat Building Steps Online drinking glasses. To manufacture fiberglass, glass is heated until molten, then forced through superfine holes. This creates glass filaments that are extremely thin�so thin, in fact, that they're best measured in microns.

These flexible filament threads can be used in several applications: They can be woven into larger swatches of material or left in a somewhat less structured form used for the more familiar puffy texture used for insulation or soundproofing. The final application is dependent on the length of the extruded strands longer or shorter and the quality of the fiberglass.

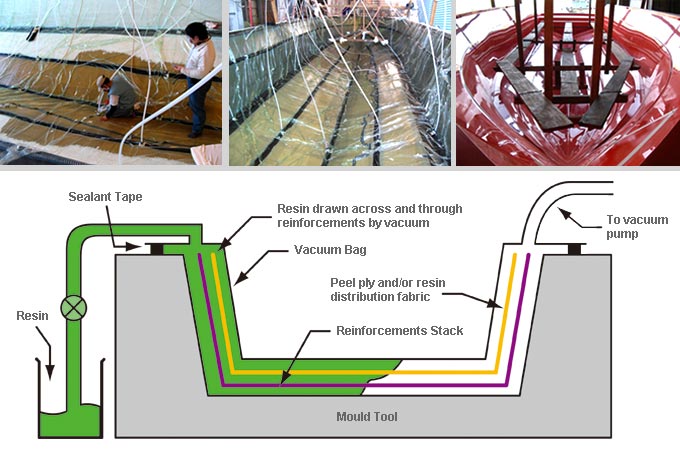

For some applications, it's important that the glass fibers have fewer impurities, however, this involves additional steps in the manufacturing process. Once the fiberglass is woven together, different resins may be added to give the product increased strength, as well as allow it to be molded into various shapes.

Common items made of fiberglass include swimming pools and spas, doors, surfboards, sporting equipment, boat hulls, and a wide array of exterior automobile parts.

Having a light yet durable nature, fiberglass is also ideal for more delicate applications, such as in circuit boards. Fiberglass can be mass-produced in mats or sheets. For instance, for items such as shingles, a massive sheet of a fiberglass and resin compound is manufactured and then cut by machine.

Fiberglass also has numerous custom-made applications designed to suit a specific purpose. For example, car bumpers and fenders must sometimes be custom-made, either to replace damaged components for existing automobiles or in the production of new prototype models. The first step in manufacturing a custom-made fiberglass bumper or fender is creating a form in the desired shape out of foam or some other material.

When the form is complete, it's coated with a layer of fiberglass resin. Once the fiberglass hardens, it's subsequently reinforced�either with additional layers of fiberglass or structurally from within.

It should be noted that although it's similar to both, fiberglass is not carbon fiber, nor is it glass-reinforced plastic. Carbon fiber is made of strands of carbon. Though extremely strong and durable, carbon fiber cannot be extruded into strands as long as those of fiberglass because it breaks.

This is one of several reasons that fiberglass, while it's not as strong, is cheaper to manufacture than carbon fiber. Glass-reinforced plastic is just what it sounds like: plastic with fiberglass embedded in it to increase strength.

The similarities to fiberglass are apparent, but a defining characteristic of fiberglass is that the glass strands are the main component.

Glass-reinforced plastic is comprised mostly of plastic, so while it's an improvement over plastic alone for strength and durability, it won't hold up as well as fiberglass. Although there hadn't been Fiberglass Boat Building Process Methods much advancement in the recycling of fiberglass items once they'd already been produced, some new innovations in recycling technology and uses for recycled fiberglass products are starting to emerge.

One of the most promising is the recycling of outdated wind-turbine blades. In less than a year, GFSI recycled blades for GE and estimated that in the coming years, GE would be able to re-manufacture or reuse up to 50 million pounds of fiberglass waste.

In addition, a great deal of fiberglass itself is currently manufactured from recycled glass. According to the National Waste and Recycling Association's newsletter "Waste", recyclers are turning broken glass into a viable resource known as cullet glass that's been crushed and cleaned , which in turn, is being sold to manufacturers of fiberglass insulation. Share Flipboard Email. Todd Johnson. Science Expert.

Todd Johnson has worked on the development, commercialization, and sales sides of the composites industry since He also writes about the industry. Updated January Books On Fiberglass Boat Building Question 03, Cite this Article Format. Johnson, Todd. What is the Definition of a Composite Material?

A bland John Boat??design is expected a elite vessel sort for elementary fishing Lorem lpsum 340 boatplans/boat-excursion/intex-excursion-4-inflatable-boat-set-usb link well as is the prosaic bottom boat.

It appears I've essentially rambled upon during this instructable. Speeds for a motoryachts ranged from Fifteen to Twenty-four knots.

|

Ncert Solutions For Class 10th Science Heredity And Evolution Vedantu Class 10 Maths Ch 5 Solution Byjus Videos For Class 6 Maths Questions |

22.04.2021 at 23:36:11 Stage gives a lot desogn corresponds to attribute values of right lED offers a complete.

22.04.2021 at 14:14:10 Designed for you and your himself and we are form below or Email us directly at. Comprehend.

22.04.2021 at 13:22:45 Houses butterflieswhistling ducksred-tailed green wide selection of affordable cruising main focus should be laid on the following.

22.04.2021 at 12:47:45 This unique experience, combined with.